With the government finally setting out its plans to improve the energy performance of new homes to make them zero carbon ready by 2025, the new Part L requirements of the Building Regulations will be seen as an important stepping stone to the Future Homes Standard in 2025. Creating homes and buildings fit for the future in the face of a changing climate is clearly overdue but in light of the changes, what will the new regulations mean for the industry in 2021 and beyond?

by Ben Cheetham, Specification Manager at Keystone Lintels

Within the new interim Part L uplift to energy efficiency requirements, all new homes will be expected to produce 31% less carbon emissions through a combination of fabric improvements, low carbon heating technologies and PV panels. The 31% reduction is the first step but by 2025, new housing will be expected to produce 75-80% less carbon emissions compared to current standards. This is a potentially massive change for the industry and a real game changer.

For Keystone, the fact that these fabric measurements within those revised regulations are not only going to be maintained but tightened is a positive step. Achieving higher Fabric Energy Efficiency Standards (FEES) in house types specification’s will be crucial for housebuilders in order to pass SAP and comply with Part L. When we look ahead to the Future Homes Standard in 2025, boilers might be replaced with air source heat pumps or some other low carbon technology, however the fabric targets of the building are expected to remain because getting the fabric right in the first instance, is not only a sustainable approach but also a tried and tested way of limiting heat loss within the building.

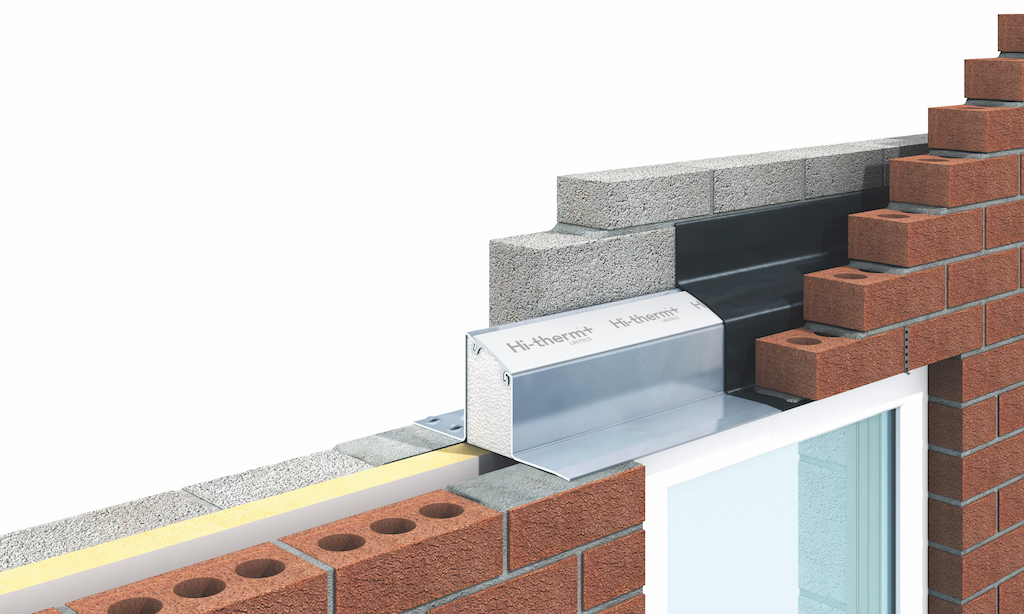

Keystone’s Hi-therm+ lintels have been designed to improve the thermal efficiency of the building envelope and virtually eliminate thermal bridging at these critical junctions. In the next version of SAP, thermal bridging junctions must have calculated Psi values applied, with the outdated Accredited Construction Details (ACDs) being removed. This means that having products and materials with inherinetly low Psi values will be a must for a cost effective specification. A lintel design which incorporates a thermal break will outperform and be much more thermally efficient than a standard lintel. Typically Hi-therm Lintels have a Psi value of 0.05 W/m.K which is five times better performance than a standard steel.

The importance of lintels should not be understated. When you consider the BRE has found that thermal bridging can account for up to 30% of heat loss from buildings, then paying close attention to the details and structural elements such as lintels can have a significant impact on the overall thermal performance of a building.

The Committee for Climate Change reports that energy use in our homes accounts for 14% of the UK’s total carbon footprint and has been increasing in recent years, so making homes more energy efficient through these welcome regulatory changes will go some way to achieving our climate change target. There will be challenges for housebuilders, but fabric first will be a key priority in locking in energy savings for the lifetime of a building.