Wavin, a leading manufacturer of plastic piping systems, has launched a new Inspection Chamber Selector to help customers choose the best products for their projects.

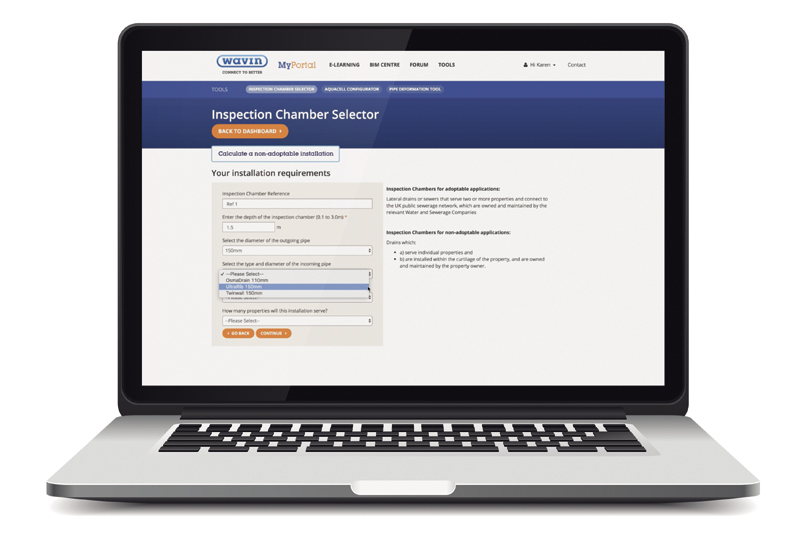

The new online tool asks users four questions and from the responses it generates the options available and specification required. When selecting an inspection chamber, there is often more than one solution available to meet a particular project requirement. With this in mind, Wavin’s Inspection Chamber Selector offers a choice of relevant components which can be used.

The questions about the project include the diameter of outgoing and incoming pipe and the number of properties the installation will serve. From this information, the Inspection Chamber Selector will then generate a report detailing the different solutions available for the given specification. The report also provides corresponding part numbers for each component selected, meaning specifiers and contractors can take the report to a merchant to fulfil the order.

Martin Lambley, Product Manager for Foul, Utilities & Water Management, commented: “We have an extensive range of inspection chambers available across our portfolio for many different applications. However, this can make product selection a time-consuming task.

“We therefore created the selector tool to better guide our customers in choosing the most suitable products for their projects. Since users can only select components that are compatible with one another, the tool also gives customers the added reassurance that the inspection chamber they select will work effectively within the entire foul water system.”

The Inspection Chamber Selector features components and chambers from across the Wavin, OSMA and Hepworth Clay product ranges. Wavin’s inspection chamber range includes shaft diameters from 200mm to 600mm, with both single and multiple inlets and outlets from 110mm to 300mm.

To use the Inspection Chamber Selector click here.