Manhole covers and gully grates are amongst the first materials installed on a site to protect drainage and other water entry points. As a result, housebuilders need to be mindful of protecting them from heavy plant equipment used during the construction phase. Gosia Kwapisz, Product Manager at Wrekin Products, explores how ironwork damage can be avoided with the use of protector shells.

Without protection, on its own, a manhole cover or gully grate will only be able to withstand the final traffic environment it was intended for. At a new-build residential construction development, this means that if anything over the weight load of typical traffic – such as cars, vans or delivery lorries – passes over, then damage is likely to occur. This can cause cracking to the ironwork or, in more severe cases, will require manhole covers or gully grates to be entirely dug out and reinstalled with the risk of further product damage in the future.

Both repair or complete replacement scenarios would mean additional time worked, costs incurred and potential complications in the future to contend with. To avoid these issues, developers need to ensure that the right protection for ironwork is specified at the right time.

Load protection

During the construction phase, manhole covers and gully grates must be protected from the correct traffic loads. At the initial building stage, this is typically anywhere from group four D400, pneumatic tyres, to greater impact group five, which includes tracked plant and machinery.

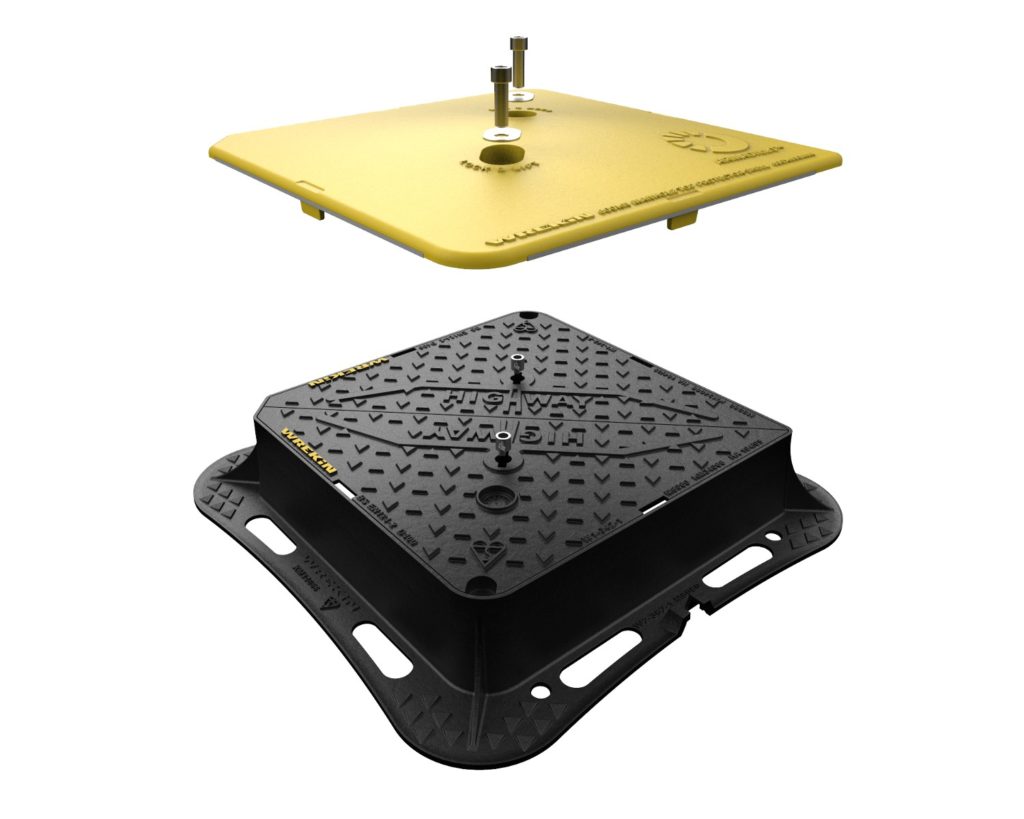

The idea of a protector shell for ironwork is to provide additional temporary protection to ensure that manhole covers and gully grates can withstand the heavier force of construction plant tracked vehicles, forklift prongs, digger buckets and more. The Armadillo range of manhole cover and gully grate protector shells provides protection from group five traffic during the construction phase of a project and can be easily removed when the final surfacing is completed.

Added benefits

As well as providing the essential tough exterior required to cope with extreme loads, Armadillo protector shells can offer additional benefits. For instance, stopping debris from entering the chamber and drainage system at the source and eliminating the need to jet wash, saving time and expense. Furthermore, the bold yellow coated shells are easier for operatives to identify as separate to other ironwork.

Housebuilders and developers have a duty to complete construction considerately and avoid issues that could lead to complaints from residents and road users. This means protecting the surrounding ironwork during the construction process and reaping the benefits that come with avoiding costly renewal and re-installation of the ironwork – showing It always pays to not forget the ‘hard hat for ironwork’.