Housebuilders need to make the shift to low carbon heating systems, but where to start? Laurie Moulding, Key Account Director at WMS Underfloor Heating explains.

With the Government’s Future Homes Standard on the horizon, housebuilders need to turn their attention away from gas boiler installations and traditional convection heating systems. Wall-mounted radiators will likely become a thing of the past.

Read: PHPD’s product spotlight – heat pumps

Even with the promise of a few years to get our ducks in a row, this is still a significant challenge for all involved, from housebuilders to the HVAC industry, to the end user. As an underfloor heating specialist, we’re receiving an increasing number of calls from housebuilders who want to instruct their technical departments to look at what the Part L changes mean for them, and examine their options for renewable energy alternatives.

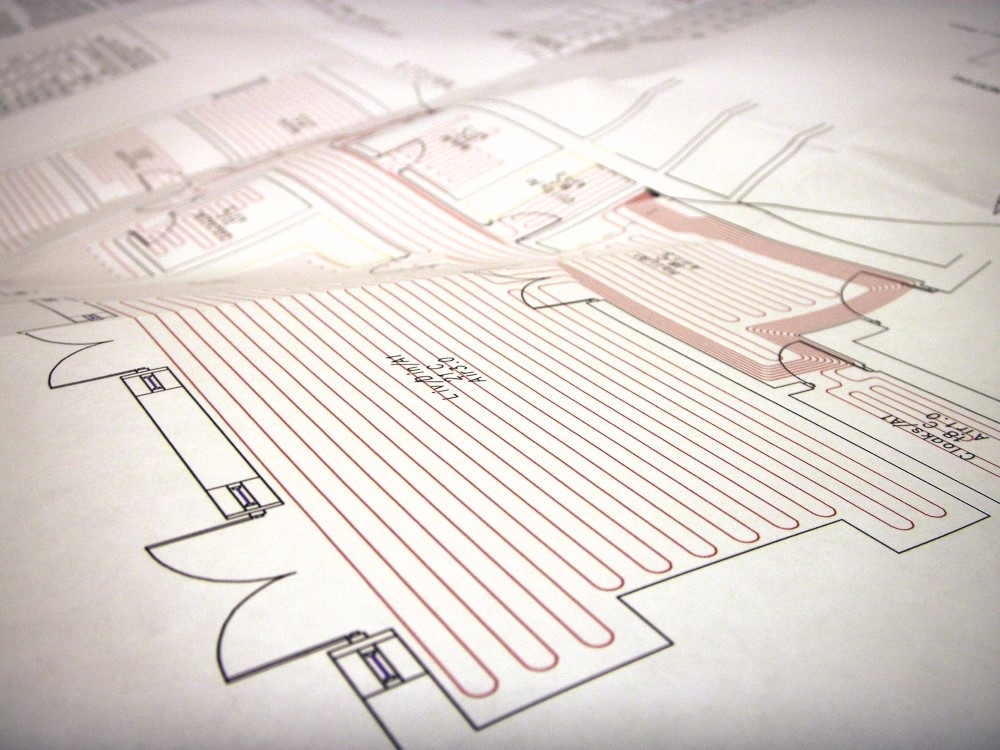

On the whole, the focus seems to be for heat pumps, which are a perfect partner for UFH systems, producing the low water temperature (40°C) required and as a system, is more energy-efficient and cost-effective to run compared to radiators. They’re also space-saving – something which is a different story for any housebuilders still considering wall-mounted radiators. In fact for radiators to be a viable option, they’ll need to be at least twice their current size to deliver the same amount of heat at a lower temperature, therefore demanding premium wall space and creating a headache for room designers.

But while the technical data adds up and the products are available, it’s no easy process shifting to an entirely new heating system. But, to help get things started, here are three key areas I’d suggest focussing on for a heat pump/UFH system:

1. Find a trusted UFH supplier

For the specification, design and installation you ideally need to find one point of contact who can manage the entire process from start to finish. By this I mean a provider who can, along with their underfloor heating designs, bring together for you the ideal cast of 1) The heat pump manufacturer and 2) An F-gas registered heat pump specialist, as this will ensure your heating system is sized correctly for maximum efficiency. Most would remember that 8-10 years ago heat pumps had a very bad name in the industry and the same will happen again if inexperienced teams take hold. With these three all working together, your point of contact should be able to incorporate all works into your build programme, without you having to address the finer details yourself

2. Train your sales and marketing team

Your objective is to sell new homes, but the homes we’re talking about now are using a heating system which is alien to most of us. So, your sales and marketing teams need to know how to promote the benefits of low temperature systems and be able to explain how they work. Your provider should also be able to help with this.

3. Educate your homebuyers

Your buyers will be the ones living with the new heating system and so need a user-friendly guide to aid their understanding. At WMS we have a homeowner’s strategy which clarifies how our systems work as well as how to operate and maintain it – and on the latter point, I should also say that UFH systems require very little maintenance and you would only need to have your heat pump serviced once a year, in the same way you would for a boiler, but by an F-Gas registered engineer.

Getting organised early is key and I’d suggest engaging in these changes over the next 12 months is essential for any housebuilder who wants to be ready to hit the ground running by 2025.