With thermal bridging proving to be the final frontier when it comes to improving a dwelling’s energy efficiency, Zoe Watson, Group Marketing Manager at Birtley Group, looks at the options available to developers.

Lintels are an essential structural element wherever there is an aperture in a wall such as those for doors and windows. However, it has to be remembered that not all lintels are the same and choosing one without a thermal break can compromise the thermal performance of the whole dwelling. Conversely, latest generation lintels that incorporate a thermal break can be equivalent to upgrading your development from double to triple glazing, yet at a fraction of the cost.

Standard lintels made from a single piece of highly conductive steel interrupts the line of insulation in the cavity wall, which causes thermal bridging. This is where there is a significantly higher heat transfer than the surrounding, insulated elements.

With a typical dwelling having 8-10 windows and two doors, thermal bridging through single-piece lintels can account for around a third of the total heat loss. As such, taking steps to minimise thermal bridging along the lintel can be a very cost-effective, reliable and robust method of achieving compliance with building regulations, whilst making the property more energy efficient and desirable to potential buyers.

Energy efficiency target

Recent changes to Building Regulations mean that a dwelling’s fabric performance must now hit a Target for Fabric Energy Efficiency (TFEE) in addition to the traditional Target Emission Rate (TER) for CO2. This means that more emphasis is put on reducing heat loss, a significant proportion of which can be attributed to lintels and other non-repeating thermal bridges.

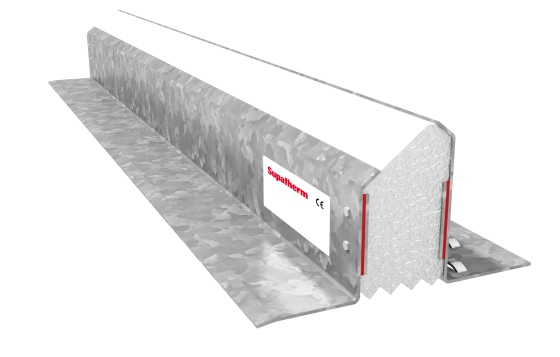

The thermal bridging performance of a lintel is expressed in terms of its Psi value. Latest generation lintels such as our Supatherm range are able to achieve a Psi value of between 0.03 and 0.06. The lower the Psi value, the better the thermal performance. Energy assessors, when working on a building constructed to Part L Accredited Construction Detail, tend to use an approved value of 0.3W/mK for lintels without a baseplate. In reality, a heat loss of 0.3W/mK makes the assumption that the line of insulation is interrupted with a highly conductive, traditional steel lintel.

However, this does not reflect actual heat loss from latest generation, thermally broken lintels. For instance, even with our 1500mm standard lintel the Psi Value is 0.18 W/mK, although upgrading to our Supatherm lintel at the same length improves thermal performance to 0.043 W/mK. Replacing a traditional lintel made from a single piece of metal with a thermally broken lintel can therefore cut heat loss through thermal bridging by over 75% and make significant improvements in SAP calculations.

Performance benefits

In terms of actual performance, a thermally broken lintel can improve both the dwellings CO2 emission rate (DER) and fabric energy efficiency rate (DFEE) by 3% and 1% respectively. In the case of a small detached dwelling of around 105m² the reduction in heat loss from a thermally broken lintel is equivalent to upgrading from double to triple glazed windows.

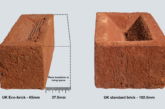

The impact of upgrading to a super-insulated lintel is even greater on a larger detached dwelling of 304m², which can mean the cavity wall thickness is reduced from 150 to 125mm. This is another significant saving for developers in terms of insulation and masonry ancillaries. It also avoids the loss of internal living space as wider cavities have a tendency to encroach on the internal footprint.

When it comes to specifying structural load bearing elements in the external walls, a thermally broken lintel can make a significant improvement in energy efficiency. As a consequence, there is growing prominence on the Psi value (W/mK) measure, and the reason why we make these freely available. Accredited energy assessors are able to use this data with their thermal modelling software to calculate accurate heat losses at junctions, rather than simply assuming, incorrectly if a thermally broken lintel has been installed, that it is 0.3W/mK.

As incremental improvements in energy efficiency become ever more expensive, simple steps such ensuring your properties have thermally broken lintels can make a significant difference to overall performance. If you choose a thermally-broken lintel, make sure you let your energy assessor know so that they don’t unfairly downgrade your properties – potential buyers do take note of a dwellings energy performance.