PHPD visits the Mitsubishi Electric manufacturing facility in Livingston to learn more about the new energy efficient features on the company’s latest range of Ecodan Air Source Heat Pumps and cylinders.

We all know fuel bills are on the rise, and rising with them is the level of awareness potential purchasers of new property have of energy efficiency characteristics of their new home. Developments that add value to a home by utilising solutions that keep bills down will be increasingly sought after in the future.

At the same time the newbuild standards are gradually being tightened too. Part L requirements have been revised over the years to encourage more efficient builds, and the upcoming Zero Carbon Standard will drive the energy efficiency characteristics of new homes even further.

Coupled together these trends pose an opportunity for housebuilders. Those that get ahead of the new regulations and build energy efficient homes with the promise of low energy bills will have a jump on the market.

Pump it up

Ways to increase the energy efficiency of heating and hot water generation have been available for some time. One option familiar to most is an Air Source Heat Pump (ASHP). It uses a small amount of electricity to extract naturally occurring heat from the outside air, for use indoors via radiators, underfloor systems or for hot water – and ASHP is a solution that is expecting substantial growth in the coming years.

The total domestic heat pump market was around 24,000 installations in 2013. This is predicted to grow to around 76,000 installations per year by 2018. Looking further into the future, the Government’s strategy is to have towards 3 million installed by 2025.

To take advantage of this potential market leading manufacturers have been updating their product offerings. Mitsubishi Electric has around 40% of the UK Air to Water Monoblock market in ASHPs and it has recently launched its next generation of Ecodan air source heat pumps. The range features a number of new initiatives that the company believes will increase efficiency by 17%.

“This is our fifth generation of heat pump solutions and we have looked at just about every aspect so that we can maximise efficiency and ease both installation and operation”, explains Max Halliwell, Product Marketing Manager for the domestic Ecodan range.

The developments include the UK’s first use of a plate heat exchanger in a domestic cylinder and patented Scale-Stop technology to remove the risk of limescale build-up. Ecodan is also the only air source heat pump that has received the Noise Abatement Society’s ‘Quiet Mark’ and will now also offer intelligent room sensing as standard.

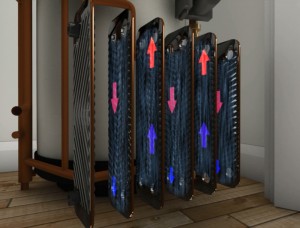

Natural convection (left) and mechanical convection

New cylinders

The FTC5 range includes a new range of cylinders which focus on improvements in heat loss performance, hot water recovery efficiency, and ease of installation and use. All ten of the new cylinders dispense with the traditional internal coil method of water heating and instead use an external plate heat exchanger which increases hot water heat up efficiency by 17% over previous models. “We think that this will grab the headlines because it challenges the traditional ways of heating a cylinder,” comments Max Halliwell.

Plate heat exchangers use forced convection to heat the water cylinder, rather than the natural convection of a coil and this increases the Delta T, meaning that the water heats up more quickly and recovers temperature quicker when some hot water is used. However, many parts of the UK suffer from limescale in the water supply and plate heat exchangers are more likely to scale up and drop in performance, which is why the company has developed a patented Scale-Stop technology.

The system promotes the precipitation of scale inside the trap rather than on the plate in the heat exchanger and maintains the high performance for over 10 years, even in hard water areas. “We have solved the problem of limescale for plate heat exchangers with this technology”, explains Halliwell.

How the plate heat exchangers work

Energy monitoring

The new Ecodan products also feature energy monitoring which, notes Halliwell, “will now be installed on every Ecodan that leaves the factory.” He continues: “We see this as a key way of demonstrating the effectiveness of heat pumps moving forward.”

The three different options available are; The standard level (which is pre-installed at the factory) offering remote energy monitoring using partial estimation of energy use; Level Two includes the addition of an electric meter; and Level Three which adds a Metering and Monitoring Service Package (MMSP) heat meter.

“We believe that this is one of the strongest ways of demonstrating our faith in the possibilities for the heat pump market”, adds Halliwell, “the ability to monitor and measure energy consumption… will become increasingly important as energy prices continue to rise. Adding this facility will allow homeowners to measure and maximise system efficiency and minimise run costs.”