Quality is the answer to long-term integrity of brick-built properties, says Scott Denham, Sales Director, IG Masonry Support.

If the properties we build today are to remain standing for generations to follow, quality must be central at all stages of the construction process. Hitting the mark on quality, offsite construction is helping housebuilders and developers create buildings that embrace the traditional beauty of brick through the utilisation of hygrothermally-tested brick slip soffit solutions. But how do these systems combine modern engineering and familiar aesthetics with safety and long-term performance?

Brick has been used by housebuilders and developers for many years, mainly because of its consistent shape, compressive strength and ability to absorb water. Brick buildings leave a lasting legacy, as they can endure the test of time for many years and still look as good as they did when completed.

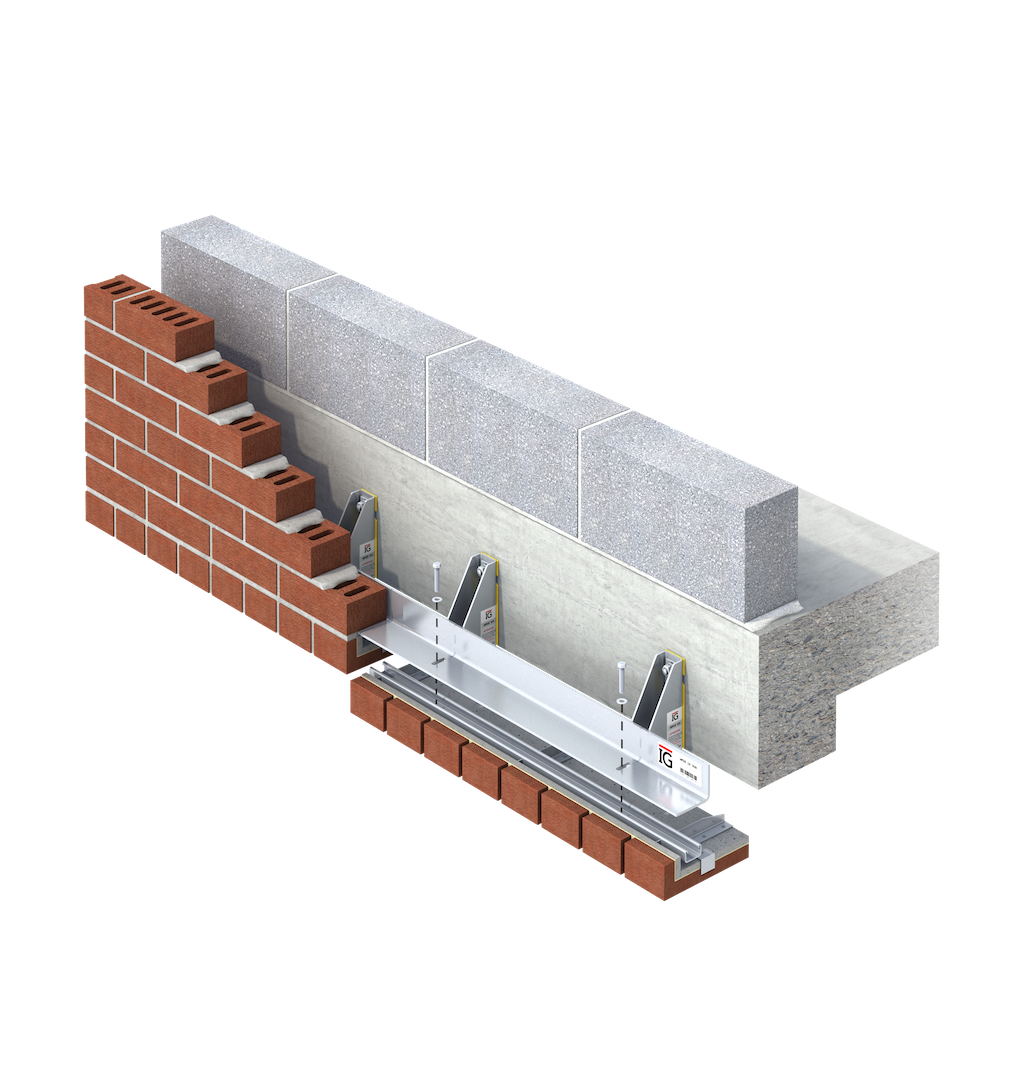

The intricate detailing that brickwork enables is like no other and can be utilised to ensure a brick-based building sits perfectly within its surrounding environment. Brick detail in the form of brick soffits, deep reveals and flying beams continually make for stunning exteriors, enabling truly unique detailing to be created. It is no surprise then, that brick continually proves to be of popular use among housebuilders, as quality and significant aesthetic impact can be achieved.

With these designs in high demand, offsite manufactured brick slip units fill a huge gap in the market. Intricate designs are no longer solely reliant on the domain of skilled craftspeople; they can be created in the quality-controlled, efficient environment of a factory, without the need for any lengthy and costly fabrication onsite.

New processes

Construction processes and regulations are continually changing. As such, product manufacturers have to change and adapt, to ensure their products conform. In recent years traditional brickwork has been paired with a more modern form of fabrication that assures quality, intricacy and long-term value: offsite manufacturing. Many housebuilders and developers are looking at how factory produced systems can support the onsite processes as a way of speeding up the build process, improving safety and ensuring quality and conformity.

Offsite manufactured solutions can be utilised to create intricate brickwork detailing that would be costly and complicated to fabricate onsite. It takes time and skill to create complex and uniform brickwork detailing to a project’s brief, yet with prefabricated solutions this level of detail and replication isn’t an issue. Taking the construction of complex brick features offsite into factory-controlled conditions drives the level of quality and consistency that is needed to achieve excellence.

Testing, testing

Many manufacturers weather-test prefabricated products so they know the solutions are built to last. The external walls of buildings are exposed to a wide range of weather conditions including: wetting and drying, heating and cooling, freezing and thawing, to name but a few.

IG Masonry Support recently launched its BBA Certified B.O.S.S. A1 system, a hygrothermally-tested, carbon neutral product which is ‘A1’ fire rated and suitable for use on projects that require Building Regulations Document B compliance.

The B.O.S.S. A1 units were tested to demonstrate structural performance, following a period of accelerated weathering. The bond strength of the system was evaluated after being subjected to hygrothermal conditioning in accordance with EAD090062-00-0404. The testing involved subjecting the B.O.S.S. A1 units to repeated heat/rain cycles, followed by repeated freeze/thaw cycles at a controlled temperature and humidity, all designed to simulate naturally occurring conditions. This testing validated the physical performance and long-term durability of all components as well as ensure the products are fit for purpose and conform to regulations.