Most developments require site hoarding to provide a barrier between the general public and a busy building site. PHPD questioned Colin Wheatley, Product Manager at MEDITE SMARTPLY, about the requirements for site hoarding and the company’s latest solution.

What are the key requirements for site hoardings on a housebuilding site?

The primary responsibility of site hoarding should always be to keep those inside and outside of the building site safe. In order to do that the material used must be strong enough to withstand natural forces, such as wind and rain, as well as put off people that are trying to access the site for their own safety.

From a contractor or installers point of view there are many additional benefits that separate good products, from the bad. When designing this product, we took note of the Temporary Works Forum’s (TWF) Guide to Good Practice on hoarding. This led us to consider: weight, length, width, ease of install and so on.

The ultimate goal for is to contribute toward making site hoarding safer and more efficient for all involved.

Is there any official guidance that should be followed?

While there is no official guide, we’ve taken note of the TWF’s Guide to Good Practice on hoarding. We are also members of the Association of Fencing Industries (AFI) who also drive for safer, more efficient fencing of all shapes and sizes, including site hoarding.

We recently attended an AFI meeting and were surprised at just how concerned contractors and installers were of the safety and potential risks imposed by poor practice and poor products when it comes to site hoarding. Concerns, such as the delamination of plywood for example, can lead to hoarding taking flight in a breeze and injuring passers-by.

There are also the environmental credentials to think of. With many of the larger contractors and housebuilders looking to achieve credentials such as BREEAM all materials brought onto site during and post construction need to be of a certain standard. It’s therefore important to know where your site hoarding comes from, and what kind of timber it’s made from.

How does SITEPROTECT differ from standard OSB?

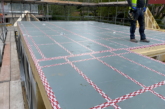

SMARTPLY SITEPROTECT is the highly engineered, moisture resistant, pre-primed OSB3 panel specifically designed to save time and money in the most demanding hoarding applications.

The panels come pre-primed with a heavy-duty, cross-linked polymer primer, is structurally sound and can be manufactured in sizes of up to three metres high, ensuring maximum security.

With only the top coat to apply, this not only saves contractors hours in time and energy, but makes it ideal for use in a wide range of hoarding applications.

All of our SMARTPLY OSB is FSC certified timber from our own sustainably managed Irish forests.

Why has it recently been made available in a thickness of 16mm?

By popular demand, and in line with the Temporary Works Forum’s (TWF) Guide to Good Practice, SMARTPLY SITEPROTECT is now being manufactured in a thickness of 16mm, making it lighter and easier to handle, without compromising on structural integrity.

Site hoardings provide a great canvas onto which a housebuilder can add strong marketing statements. Does SITEPROTECT need priming or painting?

In a nutshell, no. It comes pre-primed meaning you can simply erect it, paint it on the face and edges and get on with the rest of your day. We are looking to save contractors time and, ultimately, money with this product, while providing a safe and secure barrier to your site.

With only the top coat to apply, this not only saves contractors hours in time and energy, but makes it ideal for use in a wide range of hoarding applications