Matthew Rolph, Managing Director at Graf UK, looks at the products and legislation steering the market for efficient off-mains wastewater treatment – and explains what developers need to know to make the right choices.

More and more housebuilders are choosing to develop in rural parts of the country, with recent proposals to build on London’s greenbelt a prime example. Such projects often fall outside the mains drainage network, which makes finding an effective alternative to manage wastewater a key priority for developers. What’s more, with public health and environmental protection front of mind, official regulations surrounding wastewater treatment have tightened in recent years.

The good news is that today’s market boasts a growing portfolio of safe, efficient and reliable solutions for the job. The challenge is that for developers, correct specification is often a balancing act: between choosing the right product and meeting legislative requirements. So what do housebuilders and property developers need to bear in mind when considering their wastewater treatment options?

Choosing wisely

Of course, opting for the right type of wastewater treatment system for off-mains new-build projects is crucial. Poor specification can have, at best, unpleasant consequences, and at worst, disastrous ones – from bad odours and overflowing to potential prosecution under the Public Health Act 1936.

Septic tanks and cesspools are the most common solution for projects that aren’t connected to the main sewer network. However, they are typically very high-maintenance (needing regular emptying to prevent overflowing), and provide little or no treatment of the waste. This not only causes odour problems, but can also pose a health risk.

Package sewage treatment systems work by encouraging the formation of bacteria, and using this to produce a much higher-quality effluent. This can then be safely released via soakaways or reed beds. There are three types of package sewage treatment systems:

- Moving bed systems, where colonies of bacteria form on plastic materials known as ‘media’, before being mixed with the raw sewage. The bacteria then break the sewage down

- Activated sludge systems, which continuously blow air into the base of the tank, and use the resulting air bubbles to enable bacterial growth. Once the bacteria have digested the solids, the treated sludge collects at the bottom of the tank

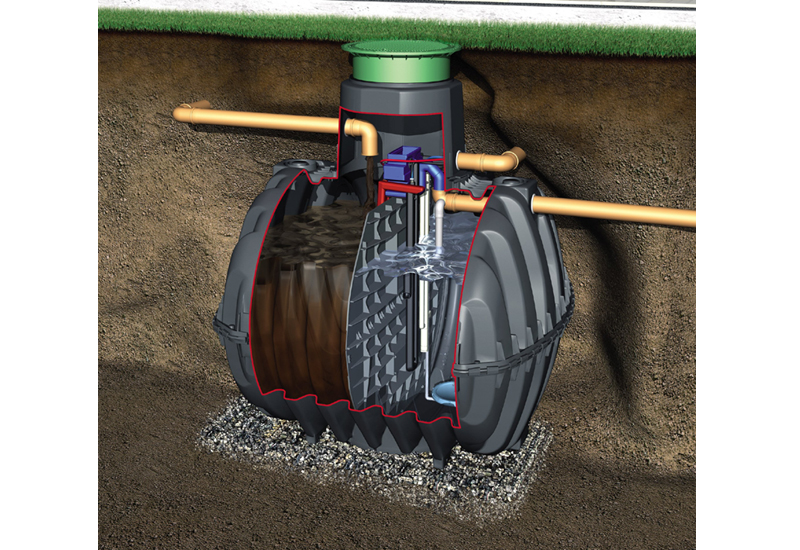

- Sequence batch reactor (SBR) systems, like activated sludge systems, work by circulating air inside the tank. The main difference is that SBR systems use a series of chambers to treat waste in batches, for more consistent, efficient performance

While all three package sewage treatment systems are viable options for off-mains projects, they each have their pros and cons. Moving bed systems, for example, can be difficult and expensive to maintain, as the plastic media inside them need cleaning and/or replacing regularly.

Activated sludge systems benefit from a simpler biological treatment process (with no plastic media involved). However, because they are in constant treatment mode, the speed of treatment depends on the rate at which the effluent enters the tank. During peak times, effluent may flow through too quickly for the system to cope effectively – which ultimately impacts negatively on the quality of the treated waste. It also makes for higher operating costs.

At Graf UK, we’re seeing a particular surge in demand for SBR systems (such as our Klaro E Professional and One2Clean ranges), which are the most advanced wastewater treatment option available today. As SBR systems treat waste in batches, the incoming flow rate does not affect the speed of the treatment process, meaning the quality of discharge is consistently high. Because aeration is intermittent, SBR systems also use much less power than activated sludge systems – and as they feature a buffer tank, the risk of untreated waste overflowing is significantly reduced. What’s more, SBR systems are durable – making them a safe, reliable and cost-efficient long-term investment for off-mains housing developments.

Navigating the rulebook

Alongside understanding the products on offer, it’s vital to comply with the rules and regulations surrounding off-mains wastewater treatment. There are a number of directives and frameworks in place to ensure the quality of treated effluent meets public health and environmental standards.

For instance, if your development is in England, you must consider Environmental Permitting Regulations (2014). Depending on the size of your project and proposed discharge method, you may need to apply for permission for your wastewater system. Small, domestic systems that release treated waste into the natural groundwater reserves (e.g. septic tanks) are exempt from needing permission, as long as they discharge less than 2,000 litres per day. Similarly, package sewage treatment solutions that use surface water drainage (e.g. SBR systems) are also exempt, up to a discharge rate of 5,000 litres per day. All other systems must obtain consent, and the rules differ in Scotland and Wales – so always check whether your project requires permission.

For instance, if your development is in England, you must consider Environmental Permitting Regulations (2014). Depending on the size of your project and proposed discharge method, you may need to apply for permission for your wastewater system. Small, domestic systems that release treated waste into the natural groundwater reserves (e.g. septic tanks) are exempt from needing permission, as long as they discharge less than 2,000 litres per day. Similarly, package sewage treatment solutions that use surface water drainage (e.g. SBR systems) are also exempt, up to a discharge rate of 5,000 litres per day. All other systems must obtain consent, and the rules differ in Scotland and Wales – so always check whether your project requires permission.

In rare circumstances, where treated effluent is extremely pure, it can be released directly into the water courses – but choosing the right system is absolutely key here. For example, the superior quality of the treated waste produced by Graf UK’s Klaro E Professional tanks has made this method possible in previous residential projects we’ve worked on. If in doubt, ask your manufacturer – and remember, going down this route requires official approval from the Environment Agency before proceeding.

Last but not least, correct system sizing in line with British Water’s Flows and Loads 4 Code of Practice is paramount. The code sets out the sizing criteria that sewage treatment systems must meet in accordance with the Person Equivalent (PE). Put simply, the PE is a formula that works out the system’s estimated flow rate and load size, based on the number of people who will be using it – which is central to overflow prevention.

Growing opportunity

As modern housebuilding projects continue to spread to more rural parts of the UK, growing numbers of developers are in the market for effective, long-lasting off-mains wastewater treatment systems. In response, the range of quality, fit-for-purpose solutions available is continuing to expand. Those who keep abreast of these product developments – as well as the official regulations governing this fast-paced market – will secure the best possible results for future projects.

To find out more about Graf UK, click here.