James Seawell, Area Sales Manager at Marley, considers how housebuilders can maintain the quality of roofing installations whilst saving on time and costs.

James Seawell, Area Sales Manager at Marley, considers how housebuilders can maintain the quality of roofing installations whilst saving on time and costs.

Recent figures from the NHBC showed that the number of new home registrations in the private sector is continuing fall due to the financial uncertainty surrounding Brexit. Some have reacted in the short term by reducing purchase prices or offering large incentives to encourage buyers. When this is combined with Government pressure to reach 300,000 new homes per year, it’s no wonder housebuilders are seeking ways to cut time and cost from roofing installations.

Yet, downgrading pitched roofing specifications can be risky, particularly when it comes to components such as battens and dry fix systems. It may save money in the short term, but could prove very costly further down the line – both in terms of finances and reputation. For example, using a cheaper dry ridge system will provide an immediate cost saving – but value engineering means there could be a risk of product failure and the added cost of repairs.

Whilst the introduction of the revised BS 5534 and NHBC technical standards have had a positive impact on roof security, a significant amount of NHBC Buildmark claims still relate to roofing, including issues like gable end staining from dry verge leaks. Indeed, when our site services team are consulted following roof issues on new build developments, some avoidable problems reported include condensation caused by lack of ventilation, compatibility issues due to substitution of inferior or incompatible dry fix systems, issues caused by a change in specification from the design stage to roof works, or insufficient fixings for the level of exposure.

Therefore, it is important that when looking to reduce the cost of roofing on new builds, consideration is not just given to the upfront material and installation price, but also how much money could be saved from avoiding costly call backs for repairs. By looking at both of these areas, housebuilders can save time and cost on pitched roofing, without compromising on quality or aesthetics.

Materials and installation

Materials and installation

One of the easiest ways to save both time and cost on a pitched roofing installation is to use some of the innovative easy-to-fix products on the market. Roofing manufacturers are continuing to invest in developing new products that give a traditional appearance in a fraction of the time. Quicker to install interlocking products are often cheaper than their traditional equivalents and reduce the length of the roofing programme, making significant financial savings on labour time. In addition, some of the newest products, like our Lincoln interlocking clay pantile, have special features which make them easier to install to more stringent British Standards.

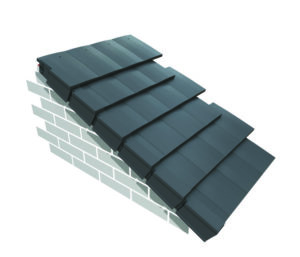

For significant time savings, look for a tile or slate that gives the required aesthetics with a higher coverage rate. Both our Ashmore double interlocking plain tiles and Edgemere interlocking slates have coverage rates of 17.5 tiles per m2, which means they are very quick to install.

Choosing accessories that make it easier to install compliant roofs can also help to save labour costs. For example, under BS 5534:2014, most single lap roofs will now require an element of roof clipping, which is a hugely time consuming roofing task. However, using a SoloFix one piece clip and nail can save around 30% on roof clipping time. To help housebuilders meet the new BS 8612 Dry Fix Standard our dry verge system now includes a Batten End Clip, which has been specifically designed with speed of installation in mind and doesn’t require nails or screws to fix into place.

Reducing call-backs

Reducing call-backs

At Marley, our specification and technical teams can work with housebuilders at the early design stages, not only to identify ways to reduce the cost and length of roofing installations but also

to help them protect the integrity of roofing specifications and reduce the likelihood of call-backs.

One common call-back for new homes is leaking roofs, or gable wall staining, which can be caused by inferior dry fix systems. To avoid this, always specify a dry fix system that is compliant with BS 8612 or has BBA certification. Also consider that not all compliant systems will offer the same levels of performance and there will still be significant differences between products. A cheap dry fix system is a false economy because it could cost more in repairs in the long term, so it is worth naming a specific manufacturer on the specification.

Indeed, many roofing claims can be avoided by housebuilders taking control of all elements of the roofing specification from the outset and not leaving anything to chance.

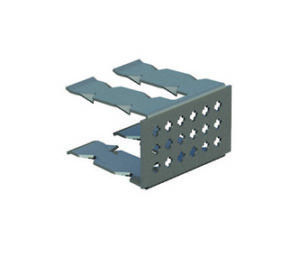

Single source

One way for housebuilders to take full control of the roofing installation is to specify a comprehensive roof system from one manufacturer, including underlay, battens, roof covering, fittings, dry fix and ventilation. This approach not only provides assurances of product compatibility and compliance with British Standards, it also reduces the risk of quality gaps and minimises the risk of unmonitored product choice or substitution further down the line.

In addition, our roof system comes with the benefit of a 15 year guarantee, giving housebuilders and homeowners peace of mind that should anything go wrong, or be challenged on-site, then there is only one supplier to deal with. Sourcing all materials from one manufacturer also saves time and money by only having to place one order and speeds up the process of getting the right materials to site.