PHPD recently caught up with David Connacher, Marketing Manager at Norbord to learn more about the company’s growing range of engineered timber solutions.

PHPD recently caught up with David Connacher, Marketing Manager at Norbord to learn more about the company’s growing range of engineered timber solutions.

Timber is one of the most familiar building materials, popular with home builders for centuries. Its well-regarded properties are further improved through engineering processes that can reduce weight, enhance strength and deliver the modern, technical solutions demanded by the market. It can also be easily handled, machined and used in a wide variety of applications. Through sustainable sourcing of raw materials engineered timber can also offer environmental benefits. Furthermore, supply chains can be kept short – for example 80% of the timber used in the plant comes from a 70-mile radius from Inverness

Q. Can you briefly explain how your OSB boards are constructed?

Norbord is the world’s largest manufacturer of OSB and has invested £145m in a new plant in Inverness, Scotland. A new family of products is a development of the most popular OSB brand in the building and interior design arena and comprises SterlingOSB Zero OSB3, SterlingOSB Zero Tongue and Groove, SterlingOSB Zero SiteCoat, SterlingOSB Zero Fire Solutions and SterlingOSB Zero StrongFix. It is a precision-engineered OSB3 board for structural use in load-bearing and challenging conditions; as well as being hugely popular in the aesthetics-led interior design industry. BBA approved and designed for humid conditions, it now contains zero added formaldehyde and is unique in the market by being the only ZAF OSB manufactured in the UK.

Unlike traditional oriented strand board (OSB) containing urea-formaldehyde (UF) or melamine-urea-formaldehyde (MUF) binders, the new SterlingOSB Zero family from Norbord uses a poly-urethane MDI resin to bind the thousands of strands that make up each board.

The pMDI binder cures at a lower temperature than UF/MUF resins so less heat energy is consumed during manufacture. It is also safer to produce since pMDI resin uses water as a catalyst in the curing process; UF/MUF resins need the addition of ammonium to harden.

Like all Norbord OSB products, SterlingOSB Zero is made from forest thinnings taken from sustainably managed forests. All of Norbord’s production sites in Europe are able to produce wood-based materials that are certified according to the guidelines of the FSC or PEFC.

Q. SterlingOSB Zero SiteCoat is often used for site hoardings – what are its main characteristics and benefits that make it appropriate for this application?

SterlingOSB Zero SiteCoat has all the benefits of SterlingOSB Zero, with the added advantages of a board created to be the perfect solution for site hoarding.

While OSB is a great choice for site hoarding, its natural texture can mean more work where painting or branding is a requirement. SterlingOSB Zero SiteCoat is readily coated and filled on one side with a non-solvent coating – meaning less work when you want to paint or graphic your site hoarding.

Q. CaberFloor P5 is well-known chipboard for flooring applications. Can it also be used to help to reduce noise transfer around a house?

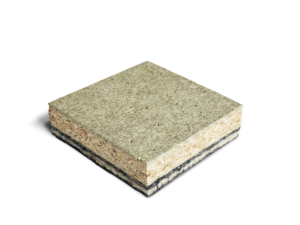

Norbord’s CaberFloor P5 has been upgraded to produce a high performance floor with reduced impact and airborne noise transmission. Called CaberAcoustic, the new product comprises 18mm or 22mm CaberFloor P5 chipboard with a 10mm acoustic felt layer permanently bonded to the underside.

Designed as a floating floor laid over an existing deck in either new-build or refurbishment applications, CaberAcoustic is installed with the tongue-and-groove joints glued with CaberFix D3 adhesive and all perimeters of the panel sealed with acoustic flanking strips.

When fitted to an existing floor in a conversion or refurbishment application, CaberAcoustic is overlaid onto the existing deck and a Hush Sound Absorber layer fitted between the joists with Hush Resilient Bars screw-fixed to the underside of the joists at 600mm centres. The addition of two layers of 15mm Soundbloc plasterboard to the underside of the resilient bar and all perimeters sealed with an acoustic sealant prior to skimming, ensures that the floor structure complies to UK Building Regulations Approved Document E for separating floor constructions in refurbishment and conversions.

In new-build applications, CaberAcoustic is laid in a similar manner (T&G joints glued and the perimeter sealed) over an 18mm or 22mm chipboard deck, but a Hush-MF system should be applied to the underside of the joists to create a void of at least 150mm from the underside of the joists to the back of the plasterboard lining.

A double plasterboard layer comprising a 19mm plasterboard plank and 12.5mm Soundbloc completes the system. Both ceiling structures also provide one hour’s fire protection.

Norbord CaberAcoustic boards are 2,400mm long x 600mm wide and are available in 28mm and 32mm thicknesses with standard TG4 edge profiles. They come in packs of 40 (28mm) or 36 (32mm) sheets.

Q. In the UK, climate external conditions can be ever-changing. How does CaberBoard react to being left exposed to harsh site conditions?

CaberShieldPlus is the ideal flooring solution when building in Britain’s unpredictable climate. Based on Norbord’s popular moisture-resistant CaberFloor P5 tongue-and-groove particleboard flooring panel, it is specially designed to withstand exposure to damp conditions.

CaberShieldPlus has protection on both sides, not just the exposed upper surface. The top surface features a permanent non-slip coating that not only prevents damage to the board but also ensures a safe working platform. The underside is protected with the smooth coating that not only protects against damage but also makes the board easy to slide into position. For added durability, the coating applied to CaberShieldPlus is not designed to be peeled off after completion but is bonded permanently on both sides of the panel and waterproof.

With CaberShieldPlus, fast-track build programmes won’t be derailed by rain, sleet or snow. BBA-approved for up to 60 days’ continuous exposure to the elements when used with CaberFix D4 adhesive, the board lets builders carry on building even with the roof off.

The 2,400mm x 600mm tongue-and-grooved panels are available in 18mm and 22mm thicknesses and are colour-coded to make it easy to identify the top surface. It is delivered in packs of 80 (18mm) or 66 (22mm).

Q. Do you think more homes will be built from timber in the future?

I think there will be. With the ever-growing capacity of modular and off-site construction, more homes can be built and put together at site when it is convenient for the house builders as opposed to fighting the British weather. We hope products such as SterlingOSB Zero and CaberDek will be used because of their popularity and heritage within the sector – joiners and jobbing builders have been using these products for years and we hope they continue to do so.