Dale Telling, Commercial Manager at Fassa Bortolo, one of the Italian leaders in render solutions, shares insight into the wide choice of external systems available to housebuilders.

Dale Telling, Commercial Manager at Fassa Bortolo, one of the Italian leaders in render solutions, shares insight into the wide choice of external systems available to housebuilders.

Many new housing schemes often feature homes that are either fully or partly rendered. What do you see as the main advantage of using a rendered finish on a new home?

Unless complying to regulations, the choice is vast but can be complicated as all systems have varying benefits. We tend to find the key factors are costs, maintenance and aesthetics.

Many newbuild homes are built using medium dense blockwork, as this can help to keep costs of building the structural shell to a minimum. However, we are seeing many new and alternative methods of construction. Rendering provides one of the best solutions for delivering a striking design and seamless, professional finish to a house.

Our Fassarend and Fassatherm systems, in particular, are designed to adhere well to masonry and can easily be applied in a matter of days. Single application products such as Fassacouche however, only require one coat, helping to keep both material and labour costs down as they are quick to apply. The integrated board systems like our new Timber Frame System require expert knowledge and more time to mechanically fix to the shell and apply all its components.

From a maintenance perspective, a housebuilder can rest assured that a quality render, which has been installed correctly will stand the test of time against weathering and any other factors that could damage or discolour the finish. Some render systems are more hard-wearing than others, but homeowners will be able to keep the surface looking its best for a number of years with very little upkeep if the correct render system is used.

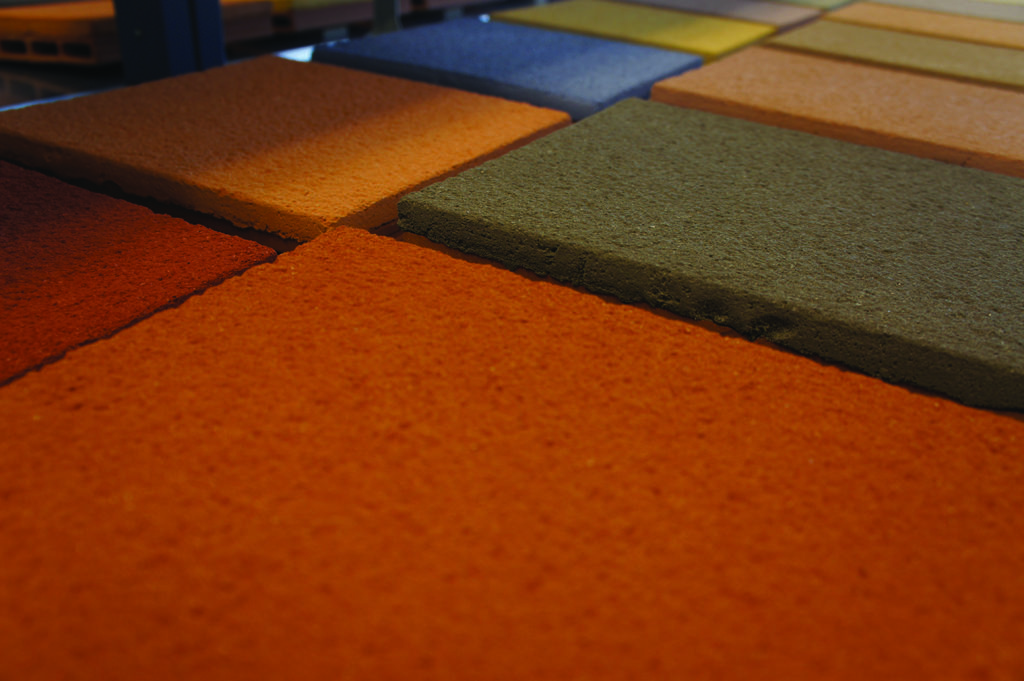

A crisp white render can be a sought-after look and is used universally within modern construction. This alone is strong enough to deliver on aesthetics, but often the colour of the render is dependent upon the area in which the building is, so the desired finish may be subject to planning. If you’re building in an area where the surrounding neighbourhood is mostly stone, chances are you will have to choose a more natural colour.

Have you witnessed growth in this area over the past year or so?

We have been selling to our customers and distributors in the UK now for five years, building up our network of valued clients. Fassa UK accounts for a small percentage of the overall revenue the company turns over each year, however, in terms of scale and growth we are doing exceptionally well and our journey is only just beginning. In 2018, our UK profits escalated by over 50%. For the future we predict a similar increase and are on target for an even more successful 2019.

Our exceptional quality products and first class service is part of the reason for our success. Our customer service extends from reliable delivery, through to pre and post-sale care including specification writing, site visits, demonstrating and clarity with our solutions. We always try to offer the most economical solution without infringing on the integrity of the system.

Can render be applied to any substrate?

Providing the specification is correct, we will try our best to find a solution for every substrate; timber or steel frame, masonry, brick or stone, newbuild or existing. We have a team of specialists at Fassa who are able to specify the correct render system based on substrate, requirements and location.

What range of colours is available and which are the most popular?

The possibilities are endless when it comes to coloured renders. We’re proud to offer our Fassatherm and Fassarend systems in 365 colours as standard, but we have also invested heavily in our distributors, purchasing a number of tinting machines, so they are able to colour match renders to existing RAL shades in store. This innovative technology allows suppliers to offer a solution to any project where colour is particular to customers. In most cases, the chosen colours tend to be more natural.

Do you also offer an insulated solution that can help to increase levels of thermal comfort?

Although more expensive and complex to install, External Wall Insulation (EWI) Render Systems can impact the cost of living, reducing fuel bills by up to 40%. Made up of an insulating panel, most commonly mineral wool or expanded polystyrene (EPS), reinforcing mesh coats and a finishing render, the Fassatherm system is attractive to potential homeowners, effective at reducing carbon emissions and can be used to build passive houses.

A lot of heat escapes through thermal bridges, a weakness in buildings whereby the levels of heat loss are higher. To name a few problem areas, these include windows (approx. 15%) and the roof (approx 25%), but by far the biggest problem for heat transfer is the walls, with around 35% of lost heat coming through them.

With the application of an EWI render system, the majority of this escaping heat is retained within the walls. The thickness of the insulation depends upon the u-value requirements, for example, building regulations currently stipulate that for a new build, the elements must have maximum u-values of 0.3, but this drops dramatically to 0.1 for a passive house. In most regeneration cases, EWI would be installed onto a solid wall construction because there is a continuous cold bridge and the insulation acts like a blanket to lock heat in. However, EWI is now commonly used on new build substrates such as steel and concrete frames.

If a housebuilder was to need some training what would you recommend?

We offer a number of training days at our HQ in Tewkesbury, Gloucestershire. Delivered over a number of days, we open our facility to housebuilders, renderers, architects and specifiers to help them understand our portfolio of systems. The days are made up of workshops with our on-site demonstrator, seminars and an introduction to our core systems and latest products. Our team of experts will be on hand to answer any questions and you can give our products go for yourself to see how they handle. These events are completely free to attend.

Our next training days are the 12th and 13th June, where the focus will be on our new Polished Plaster range, Sfide D’Arte. A stunning collection of internal plaster systems, these are a new, modern alternative to traditional wall coverings. To register your interest, email info.fassauk@fassabortolo.com

We also run roadshows across the year up and down the UK where we will be showcasing the core Fassa render systems and running live demos. Visit the website for more info on the upcoming venue dates.

For those developers and builders unaware of the Fassa Bortolo brand, can you tell us a little about the business and its history?

Fassa Bortolo is one of the leading Italian manufacturers of renders and integrated building systems. Succeeding over 300 years of manufacturing, the company has grown to open a number of distribution units across Europe including the UK, France, Italy, Spain, Portugal and Switzerland. With a firm set of values, Fassa prides itself on unrivalled product quality, its commitment to research and ethical quarrying.