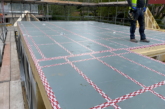

New research and rigorous testing of Egger’s flagship flooring product, Egger Protect, has shown that the structural board can remain exposed to the elements for 60 days.

This is a substantial increase on the previously cited 42 days and gives UK house builders peace of mind when dealing with unforeseen delays.

Alan White, Director of Sales for Building Products at Egger UK, explained the significance of this new development: “As a leading provider of domestic and commercial structural flooring applications, we respond to customer feedback and continually seek to improve and develop our products. We know there are many reasons why the building process can be delayed, leaving floors exposed and at risk of becoming structurally unsound.

“In response to this, I am delighted to announce that, in addition to the Lifetime Guarantee we offer on our Advanced Structural Flooring System, we also provide the only chipboard flooring on the market that, once laid, can be exposed to the British weather for up to 60 days. No matter the reason for the delay on-site, whether it be material shortages or lack of skilled tradesmen, this extended protection period is significant for any builder.”

Egger Protect is manufactured from the company’s P5 flooring grade particleboard with a weather resistant surface layer applied to both sides. As well as the 60 day protection, the board has a hard-wearing, anti-slip surface, and can be used with underfloor heating systems and tiles.

Dan Soulsby, Marketing Category Manager (Building) at Egger spoke with PHPD about the company’s recent investments and its new Advanced Structural Flooring System which includes a lifetime guarantee.

Time-saving features include a concrete-effect finish, which means no post-installation painting is required. The board can be installed during light rain conditions and is easily cleaned in preparation for handover to the customer.

CE and FSC certified, the boards are produced from sustainable raw materials. To achieve optimal results, the company’s Joint & Joist D4 adhesive must be used. The correct application of this glue creates a fully sealed working deck, protection against moisture ingress and the wear and tear of heavy site traffic. No joint sealing tape is required.