Paul Cribbens NHBC Standards Manager (House Building Standards) discusses the fixing of wall lateral restraint straps to trussed rafter roofs.

For some time it has been relatively common practice for builders to fix wall lateral restraint straps (LRS) at roof level to the trussed rafter longitudinal bracing members, although the details often used by builders do not accord with guidance offered in Building Regulations, NHBC Standards or other authoritative documents.

This article highlights situations where it might be considered acceptable to fix LRS in this way and describes proposed amendments to NHBC Standards 2017 edition to accommodate an alternative fixing arrangement.

Bracing system

Evidence from an NHBC internal survey in August 2012 indicated that LRS, used for tying walls to trussed rafter roofs, are not always fixed in the manner recommended in Building Regulations, NHBC Standards, Standards Extra 43 article on ‘Gable walls – the importance of restraint’ (December 2008) or other authoritative documents. Frequently, builders fix LRS to roof longitudinal bracing timbers rather than to noggings fitted tight between the trussed rafters at rafter and ceiling chord levels, as illustrated in the foregoing guidance documents.

Despite the emphasis placed on the importance of correctly fixing restraint straps in the Standards Extra 43 article, the results of the NHBC survey revealed that the use of the longitudinal bracing system persists particularly in England and Wales.

Although the practice does not necessarily result in any detrimental effects to restrained walls, it is difficult to prove the adequacy of the detail by calculation in compliance with British Standards. In 2015 therefore, NHBC initiated an investigation into the capacity of longitudinal roof bracing and in particular the fixings between the LRS and the bracing members, to resist horizontal forces at roof level.

Roof stability

Trussed rafter roof bracing systems are designed to provide adequate stability to the entire roof structure and it is recognised that, providing the straps are located at suitable positions and centres to accommodate the requirements for wall restraint, the longitudinal bracing members, generally comprising 25mm x100mm sawn timber, together with their fixings to the trussed rafters should be adequate to transfer the forces from the restraint straps to the roof construction.

A programme of testing was undertaken on sample assemblies comprising standard 30mm x 5.0mm thick x 1200mm long steel restraint straps fixed to lengths of 25mm x 100mm sawn timber members, as supplied for bracing timber to trussed rafter roofs. Tests were undertaken on a range of fabrications using different quantities of 4mm screw fixings in order to determine a suitable arrangement to resist the test tensile force applied to the samples.

A tensile capacity of 8.0kN was used as the target for the test samples, as this value is given in the UK National Annex to BS EN 845-1:2013 as the minimum declared tensile load capacity for tension straps that provide an equivalent performance to the prescriptive 30mm x 5mm lateral restraint straps. Tension straps of 30mm x 5mm are accepted by NHBC Standards Chapter 7.2 and building regulations guidance for provision of lateral restraint on 3-storey residential construction.

The test results indicated that eight 25mm x 4mm steel screws evenly distributed along the length of a standard 30mm x 5mm steel strap x 1200mm long would adequately resist the test tensile force when fixed to 100mm x 25mm timber longitudinal bracing members.

Optional acceptable details

NHBC will accept traditional steel LRS (30mm x 5.0mm thick x 1200mm long) fixed to the roof construction by one of the following optional methods:

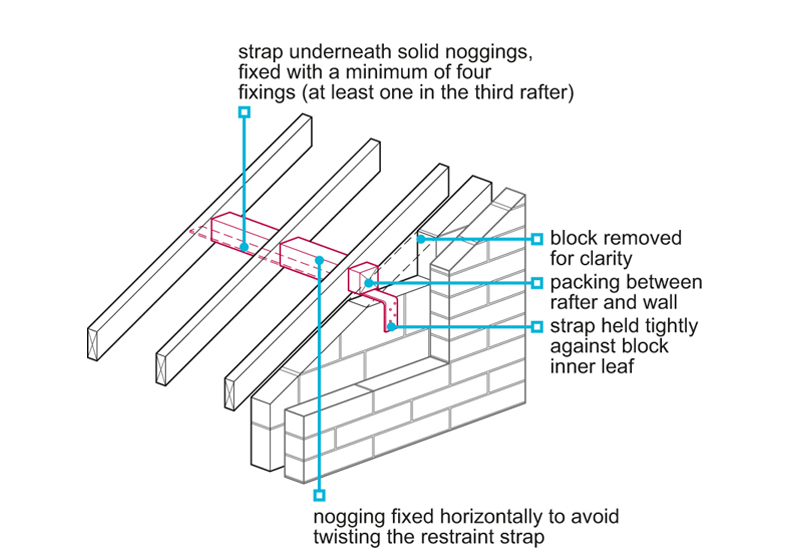

- Option 1 – LRS may be fixed to horizontal noggings fitted tight between trussed rafters and packed between the last rafter and the wall, using four 50mm minimum x 4mm steel screws or four 75mm x 4mm (8SWG) round nails, with one fixing in the third rafter as shown below (clause 7.2.8 and Figure 1).

- Option 2 – LRS may be fixed to the 100mm face of 100mm x 25mm timber longitudinal bracing members using eight 25mm x 4mm steel screws evenly distributed along the length of a standard 30mm x 5mm steel strap x 1200mm long *Lateral restraints image.

- Option 3 – As an alternative to Option 2 and where the position of the strap does not coincide with a longitudinal binder, LRS may be fixed to the 100mm face of short lengths of 100mm x 25mm timber members, which are themselves fixed over four trusses, nailed in accordance with clause 7.2.9 and fitted tight to the face of the block inner leaf.

It is intended that NHBC Standards Chapter 7.2 will be revised for the 2017 edition to permit the foregoing alternative fixing arrangements for LRS to the roof construction. The proposed draft revision to Chapter 7.2 is shown below.

Proprietary lateral restraint straps

Where proprietary lateral restraint straps that have a thickness less than 5.0mm are proposed, the foregoing options will be acceptable only when the strap is assessed in accordance with Technical Requirement R3 and the fixing arrangement complies with the manufacturers’ requirements.

The restraint clause (7.2.8) in NHBC Standards 2017 will be amended to say:

Adequate restraint shall be provided to support the structure, distribute roof loads and prevent wind uplift. Strapping shall be of adequate strength and durability, and fixed using appropriate fixings.

Restraint straps, or a restraining form of gable ladder, should be used where required to provide stability to walls, and installed in accordance with the design.

Lateral restraint straps should be located:

- for homes up to and including three storeys (two storeys in Scotland), at a maximum spacing of 2m

- for homes four storeys or over, fixed at a maximum spacing of 1.25m.

Lateral restraint straps should be fixed to the roof structure by either;

- fixing to solid noggings using four 50mm minimum x 4mm steel screws or four 75mm x 4mm (8SWG) round nails, with one fixing in the third rafter (Fig 7.2.8), or

- fixing to longitudinal bracing members using eight 25mm x 4mm steel screws evenly distributed along the length of the strap. Additionally, 100mm x 25mm timber members, fixed over four trusses and nailed in accordance with clause 7.2.9 can be used where the position of the strap does not coincide with a longitudinal binder.

Lateral restraint straps should be:

- ordered and supplied according to the design, i.e. the correct length and number of bends and twists

- in accordance with Technical Requirement R3

- provided at rafter level on gable walls, where the home is of masonry construction (larger or separating walls may require restraint at ceiling level)

- protected against corrosion in accordance with BS EN 845 – Tables A.1 and A.2 (sherardised straps or fixings are not acceptable in Northern Ireland and the Isle of Man)

- of sufficient length to be fixed to a minimum of three trusses

- a minimum size of 30mm x 5mm and have a minimum anchorage downturn of 100mm or proprietary straps installed in accordance with the manufacturers recommendations.

- fixed with the downturn on a substantial piece of blockwork, preferably fitted over the centre of an uncut block

- in accordance with BS EN 1995-1-1, where the home is of timber frame construction.

In framed roofs, as an alternative, purlins and pole plates can be used to provide restraint where the timber abuts a gable construction. Where purlins are used to provide restraint, the maximum permissible spacing is 2m unless the design shows otherwise.

Gable ladders can be used to provide restraint to the external wall where:

- there is blocking between the last trussed rafter and the inner leaf (maximum 2m spacing)

- the soffit board is cut carefully and then fixed securely to restrain the outer leaf.

Transitional measures

As a transitional measure prior to the implementation of the NHBC Standards 2017, the following will apply:

Where lateral restraint straps (LRS) are fixed to longitudinal bracing, or fixed to additional 100mm x 25mm timbers as described in this article, Building Inspectors will check to see if the fixing details are in accordance with the new guidance i.e. 8 screw fixings evenly distributed along the length of the strap etc. Where they are not, an Observation will be recorded and entered into the Site Record book to assist in future compliance.