Dan Soulsby, Marketing Category Manager (Building) at Egger speaks with PHPD about the company’s recent investments and its new Advanced Structural Flooring System which includes a lifetime guarantee.

Q. EGGER announced an increase in Turnover in its 2015/16 financial results. Which are the main areas where growth has been achieved?

Our growth comes from all areas of our business which is driven by continued investment and product innovation. Ongoing investment in new and existing production equipment allows us to produce our products in state of the art facilities meaning we can offer our customers security of supply and the best quality materials available in all our market areas.

Product innovation also plays a large part in our continued growth, again coming from all areas of the business. For example our new EGGER OSB HDX board for use in mezzanine flooring applications. This is a unique heavy duty OSB product which is 30mm in thickness. It replaces 38mm chipboard which is traditionally used for mezzanine floor applications. Despite EGGER OSB HDX being an 11% larger panel, it’s actually around 20% lighter in weight making it easier to handle and quicker to lay on site.

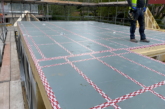

We also have our EGGER Advanced Structural Flooring System which offers a structural lifetime guarantee. By following a simple 3 step fitting process, end users benefit from the guarantee and have complete peace of mind on every floor they fit.

Q. What recent investments have been made into the business to ensure the company’s timber solutions remain highly competitive?

In December 2016 we installed and began the commissioning of a new tongue and groove line at our Hexham plant. This was a £5 million investment, replacing an aging T&G line to allow us more flexibility with production. It also includes an in-house Peel Clean surfacing facility, which means we will be the only UK manufacturer to produce a Peel Clean product on-site. The new line will also give us the potential to increase our building products output to meet the increasing demand for more homes to be built throughout the UK.

It also offers our customers the security they need, knowing that our T&G line is state-of-the-art and secures our position for many years to come.

In the first quarter of 2017 we are also investing approximately £6 million to replace one of our five lamination lines. The new line is set to secure and increase production capabilities of melamine faced boards including EGGER Protect, our market-leading structural flooring product. The investment will increase board quality and output to help us continue supporting our customers and end users.

Q. Do you believe that timber’s ‘sustainability’ message is fully understood throughout the residential construction sector?

I do believe that the UK construction market understands the sustainability of timber, however, we are still primarily a masonry construction market. Timber frame housebuilding continues to increase year-on-year in the UK. With latest STA figures confirming that in 2015 timber frame had grown to 27.6% of the UK house building market. Some of the larger national housebuilders have also announced increases going forward for their share of timber frame built homes. Other build methods such as SIPS continue to grow in popularity and now with businesses looking at offsite modular homes as a building method, they again look to timber materials such as OSB and CLT, so the use of timber is certainly increasing across all forms of residential construction.

All our UK manufactured structural flooring products are CE marked and carry FSC certification, so our customers know that our boards are produced to the highest quality using sustainably sourced materials.

Q. You offer a Lifetime Guarantee on your Advanced Structural Flooring System. What constitutes this flooring solution and this extensive guarantee?

Q. You offer a Lifetime Guarantee on your Advanced Structural Flooring System. What constitutes this flooring solution and this extensive guarantee?

The EGGER Advanced Structural Flooring System is the only system which offers end users peace of mind from a structural lifetime guarantee. Using EGGER P5, EGGER Peel Clean Xtra or EGGER Protect, along with EGGER D4 Joint & Joist Adhesive and then laying the boards using our recommended fitting system qualifies customers for our Structural Lifetime Guarantee. Further details can be found on our website www.egger.com/lifetime.

Q. What is the company’s best-selling product from the ‘Building Products’ portfolio?

In recent years we’ve seen the change in demand from basic raw P5 flooring to either EGGER Peel Clean or EGGER Protect, driven primarily by the needs of housebuilders to save time and costs.

In 2010, the majority of our T&G structural flooring sales were traditional raw P5 boards. Each year thereafter, we have seen the combined sales of EGGER Peel Clean Xtra and EGGER Protect continue to grow. So much so that we have seen a complete turnaround with coated T&G boards (EGGER Peel Clean and EGGER Protect) now forming the majority of T&G panel sales. This has been helped by the introduction of our Advanced Structural Flooring System and we only see this trend continuing, particularly with housebuilding numbers growing

Q. Reducing the build time is an objective of many involved in residential construction. What are your solutions to help shorten time on site?

Q. Reducing the build time is an objective of many involved in residential construction. What are your solutions to help shorten time on site?

This is one of the key advantages of our Advanced Structural Flooring System, which incorporates our coated T&G structural flooring boards and our D4 Joint & Joist Adhesive.

We have developed boards in both EGGER Peel Clean Xtra and EGGER Protect that allow homes to be built whatever the weather. Once laid both products can be left fully exposed to the elements for up to 42 days, meaning that weather related stoppages can be significantly reduced.

Our Advanced Fitting Guide also recommends a glue only system for fitting the boards, using EGGER D4 Joint & Joist Adhesive. This means that there is no need for mechanical fixings or joint sealing tapes, which add to the time needed on site when installing floors.

Q. Are the company’s solutions available in a BIM format?

We are the only manufacturer of structural chipboard flooring to have their materials available on 2 BIM platforms, both the National BIM Library and BIM Objects. These include all our Advanced Structural Flooring products along with EGGER Decorative Protect and EGGER OSB HDX. These can be accessed directly on the respective websites or via the EGGER website www.egger.com/building and following the link to BIM.