Nigel Sanger, Divisional Director Technical Support at JG Speedfit, discusses why MDPE fittings can reduce issues in underground mains water plumbing.

We get it every day, on tap, from bottles, from the sky. We might even take it for granted, given how freely we can get it. Yes, water is what we’re talking about.

However, when there’s an issue with the water supply, it’s a severe inconvenience. Cambridge Water estimates that on average, every person in the UK uses 150 litres of water each day. Showering, bathing, laundry, drinking, washing – when the water stops, our lives stop.

Losing the water supply is not just an inconvenience though. It can also mean a costly bill for repairs. Generally, water pipes in the street and footpath up to the boundary of a property are owned and looked after by the water supplier. However, the water pipes within the boundary of a private property are privately owned.

While insurance may cover the loss, it isn’t always guaranteed, and homeowners may be hung out to dry. Water supply problems can come back to bite housebuilders as well. To prevent this issue, it’s important we look at the source, and ensure we use the right fittings first time for water distribution.

Going underground

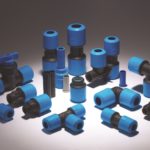

The most common type of pipe and fitting material now used to connect water mains to homes is MDPE.

MDPE stands for medium-density polyethylene, and is a robust, heavy duty material. MDPE pipe used to connect mains water supplies into homes are typically installed in underground trenches dug in virgin ground. Once installed, the trenches are subsequently filled in by heavy machinery.

Because of this it is just as important that the fittings used to join the pipework are just as strong, which is why MDPE fittings are used. It is important that these fittings can withstand the pressure when compacted by earth that is then driven over by heavy-duty vehicles like lorries and tractors.

It is at this point that a crucial choice is made – push-fit fittings or compression fittings.

MDPE push-fit vs. compression

As these fittings are being laid in the ground and buried, it is necessary that the fittings can rotate. They must have a bit of ‘give’ to accommodate the movement when earth is initially laid over, and the settlement and heave that comes later.

Compression fittings do not allow for this movement, and over time, movement can weaken the seal. The nature of compressing fittings also means a certain amount of human judgement is involved; the integrity of the connection made depends on the individual installer to tighten the fitting to an unspecified torque. This means the fitting could be too tight, or conversely, not tight enough.

As well as being robust, fittings must also be easy for installers to use at the point of installation. This is especially as installers are using them in muddy trenches that are compounded by whatever is happening with the weather on the day. Getting mud and dirt on the component parts of the fittings is of course not good for the seal’s integrity.

The possibility of dirtying the compression fitting is quite high. For instance, to connect a compression tee you will need, three compression nuts, three seals and three compressive elements, which must be assembled piece by piece onto the pipe.

With push-fit MDPE fittings, this risk is reduced significantly, because the fittings have built-in seals and the connection can be made by simply pushing the pipe into the fitting. This diminishes the chance of exposing the inside of the pipe and fittings to contamination.

JG Speedfit’s MDPE range comprises of highly engineered collets and stainless-steel teeth that create a reliable seal in even harsh weather conditions. Like other JG Speedfit ranges, no specialist tools are required and the MDPE fittings are fully demountable. This makes them quick and easy to use in tight and awkward spaces.

The push-fit nature allows the installer to easily put in temporary supplies as well as being able to use the convenient stop end. This not only prevents the property from being flooded if a stop tap is inadvertently turned on, but also prevents anything like dust, debri, worms etc. from entering the open pipework and potentially contaminating the mains later.

Protect your reputation

Protect your reputation

For the homeowner, underground leaks are not only concerning, but they face a lot of disturbance while the problem is resolved. Engineers need to be called out, and ground may need to be dug up to identify the problem. It isn’t unimaginable that any anger can be vented in the way of poor reviews and complaints, which can damage a developer’s reputation.

Push-fit MDPE fittings assure a reliable and leak-proof seal. It is advisable to look for MDPE fittings that have been manufactured to strict British standards and are WRAS approved. This guarantees they are tested and gives peace of mind to homeowners and developers that their supply pipes are constructed to the highest quality.

MDPE fittings are also designed to make maintenance, servicing, or even alterations to pipe layouts easier. Water isolation fittings, like the stop taps, allow installers to isolate the water supply in less than two turns.

It is crucial that fittings buried underground are installed correctly first time, as the cost to rectify any issues can be huge and destructive. MDPE fittings are reliable and designed to suit this type of environment.