Andy Swift, sales and operations manager for ISO-Chemie, says building regulations requiring windows to be ever more airtight will drive an uplift in energy efficient homes.

Changes to Part L of the Building Regulations are the driving force behind stricter standards and compliance procedures around energy and ventilation performance, contributing ontributing towards a roadmap to a net zero carbon future and the new homes designed and built now being built having to fall in-line with stricter carbon emissions targets. Specifically, to ensure continuity of the air barrier, window and door units will have to connect to the primary air barrier and the frames will need to be taped to surrounding structural openings using air-sealing tape.

Changes to Part L of the Building Regulations are the driving force behind stricter standards and compliance procedures around energy and ventilation performance, contributing ontributing towards a roadmap to a net zero carbon future and the new homes designed and built now being built having to fall in-line with stricter carbon emissions targets. Specifically, to ensure continuity of the air barrier, window and door units will have to connect to the primary air barrier and the frames will need to be taped to surrounding structural openings using air-sealing tape.

This comes against the backdrop where evidence points to doors and windows as the main source of the nation’s chronic energy inefficient homes. Indeed, it could be said that in the light of product innovation over the years, its perhaps ‘criminal’ that the hundreds of thousands of new or retrofit installations completed each year go unchecked or unregulated, producing a legacy of problems for years to come and costing millions of pounds to rectify. This is a pity because with advancements in cost effective, easy-to-use technologies, there’s never a justifiable reason for delaying or avoiding the specification of better energy efficient window and door sealing solutions.

Air tightness improvements

In this respect, the changes to Part L will have to be seen as a step in the right direction for the new build fenestration sector. It will see requirements for improvements in air tightness, forcing them from 10 air changes per hour down to five air changes per hour and also U-value on windows shifting from 1.6 to 1.2Wm2 k/H, which will require more energy efficient sealant solutions such as thermal foam tapes. The requirement also now states that the frame should be linked back to the wall with an airtight tape.

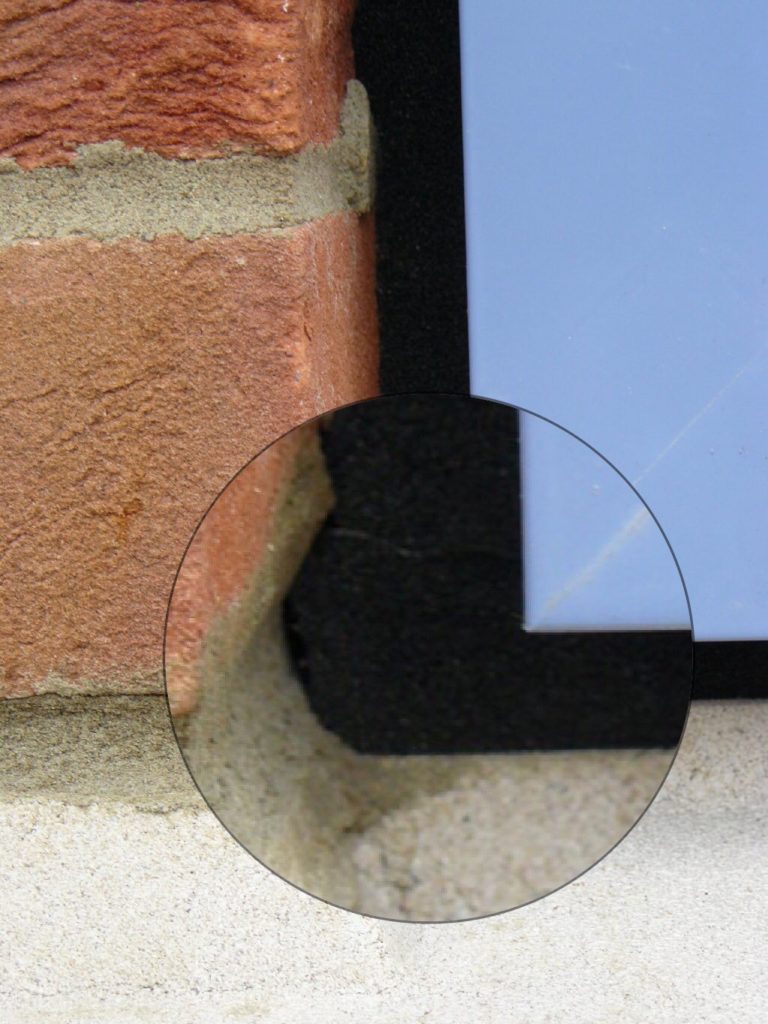

Heat will always find the fastest exit as it comes up against the A+ or A-rated window, and invariably this emanates from the 10mm or so expansion gap left around the window following fitment. This is normally left empty, but some amount of spray foam can be injected to fill the void before a silicone trim is applied for a smart looking finish. Unfortunately, as expedient as this might seem, none of these solutions create a measurable, long term, high performance thermal, acoustic or airtight barrier – the U-Value of the installed window is simply reduced, which leads to heat escape and, ultimately, financial loss.

Heat will always find the fastest exit as it comes up against the A+ or A-rated window, and invariably this emanates from the 10mm or so expansion gap left around the window following fitment. This is normally left empty, but some amount of spray foam can be injected to fill the void before a silicone trim is applied for a smart looking finish. Unfortunately, as expedient as this might seem, none of these solutions create a measurable, long term, high performance thermal, acoustic or airtight barrier – the U-Value of the installed window is simply reduced, which leads to heat escape and, ultimately, financial loss.

That’s why the house building industry and wider construction sector deserves better insulating solutions to improve energy efficiencies, particular in the face of a chronic national housing shortage and the need to build more affordable housing.

In modular construction, which continues to gain traction – industry sources estimate that out of the 200,000 homes currently constructed annually, about 15,000 of them are modular – and sees continued integration with more traditional methods of building, house designers and specifiers are looking at new ways to deliver low carbon structures, which use sustainable technologies to deliver measurable airtight, acoustic and thermal sealing benefits. And this is where self-adhesive foam sealing tapes can add real value, enabling developers to bring forward housing projects more expediently.

They can use ‘smart’ foams impregnated with different substances to create a measurable U-Value as low as 0.6W/m2k, offer superb thermal insulation and can contribute to acoustic sound reduction by 63dB. As these installation tapes are completely weather tight against driving rain up to hurricane force wind speeds, installers can quickly apply them around the frame during initial fitting. This provides the assurance that they have completed a comprehensive A-rated installation rather than just supplying an A-rated window. This is a benefit that can be sold on to deliver enhanced energy efficiency advantages for customers and property owners. Future Homes Standard

Future Homes Standard

Undoubtedly, building regulation changes are moving the fenestration industry closer to the requirements of the Future Homes Standard for dwellings. This standard, which come into force in 2025, are designed to deliver buildings which are zero-carbon ready and achieve world-leading levels of energy efficiency.

The uplift in Part L of the regulations includes a requirement for new homes to produce around 31% less CO2 than current standards and a 27% reduction of emissions from other new buildings, including offices and shops. By 2025, when all aspects of the Future Homes and Buildings Standards come into force, the Building Regulations will inevitably become even more strict, requiring new homes to produce almost three-quarters less CO2 when compared to current standards.

So, changes will have an unequivocal impact on energy standards for residential and non-domestic buildings that are far better for the environment and fit for the future – higher air and thermal standards for house construction has to be a priority.

As sustainability continues to be of paramount concern in the development of low carbon and eco-friendly building projects, we will see technologies such as energy foam tapes, which can add real value during the initial and post construction phases, only grow in importance as the most effective solutions for sealing window and door frame expansion joints and gaps in houses in pursuit of attaining the Future Homes Standard. It’s simply a matter of designing in these products.

Want to know more?

For more information, click here