Ashley Cooper, Managing Director at WMS, a supplier and installer of underfloor heating systems, discusses how underfloor heating can be specified to suit differing floor constructions, ensuring the right solution is specified for every new build, retrofit project or specialist renovation.

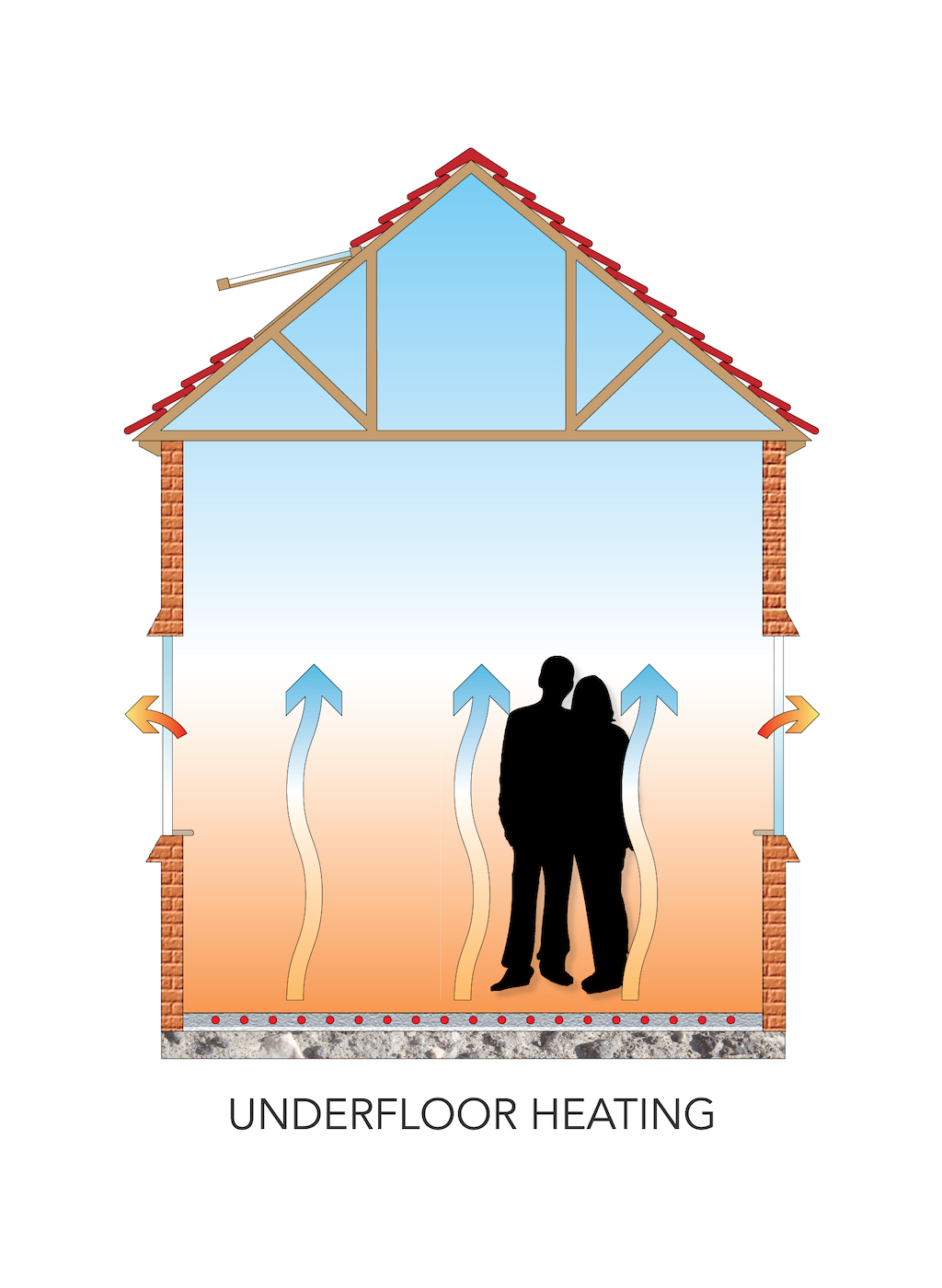

With underfloor heating offering efficiency, safety, freedom of design and the ability to seamlessly pair with renewable technologies to name a few advantages, it’s clear to see why it’s a popular choice for every property type. While all of these benefits are possible with an underfloor heating system, it doesn’t mean there is a one size fits all solution for every project and getting the system specification right for differing sub floors is essential.

Screeded

The most common method of incorporating UFH is to include the pipework within the floor screed build-up in the initial stage – in this instance, the underfloor heating pipework is sequenced before the screeding process. This solution offers a quick, cost effective and flexible form of heating within a screeded floor build-up, while also providing maximum output.

The majority of solid floor build-ups will require an insulated screed to meet building regulations – as such, it’s important to look for an underfloor heating system which can easily be accommodated into most floor applications without affecting the overall floor build-up. The AmbiClip Cliprail is our most specified system for this type of installation, as it can be fixed securely to any insulation board and is very cost effective.

To avoid any damage to the underfloor heating system, it’s advisable to schedule the screeding process immediately after installation. Also, ensure your underfloor heating contractor is notified if a liquid screed is being used, as the whole floor area must be sealed with a polythene layer to prevent screed from escaping.

Floating

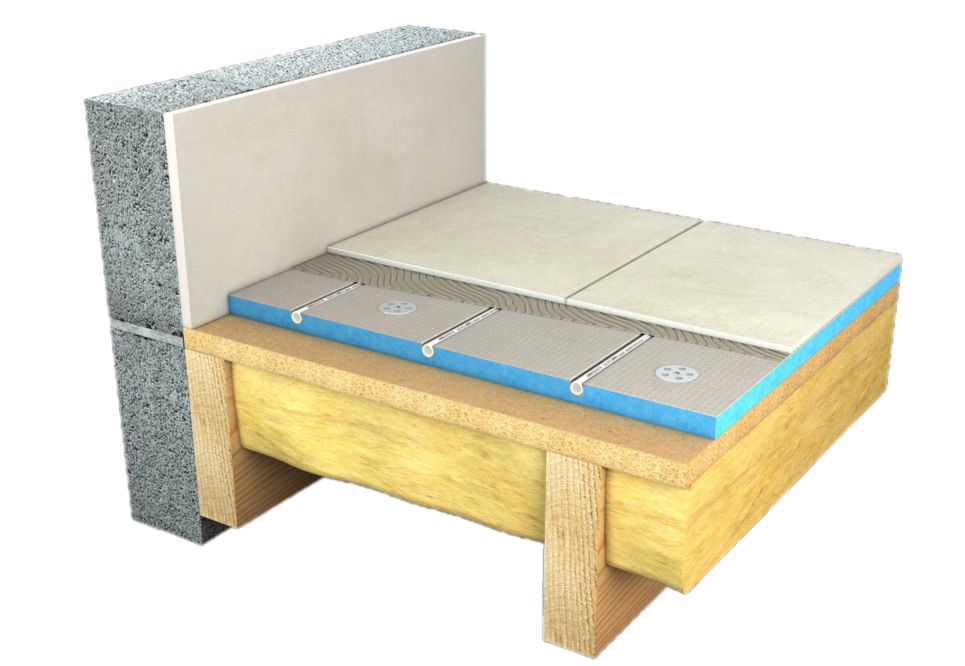

Unlike a screeded system, a floating underfloor heating system is typically laid directly onto a sub-base of concrete or chipboard, or in between timber battens, to create a bespoke system. A floating system, such as our AmbiFloat 10 solution, requires a flat and level sub floor for the insulation to fully support the floor finish on top.

With this floating solution, the insulation is part of the underfloor heating system and is pre-grooved to take the underfloor heating pipework, then overlaid with either a foil or aluminium diffusion plate to assist the distribution of heat. To ensure this system meets any bespoke requirements, each polystyrene insulation panel is manufactured per project to suit the underfloor heating design drawings.

The system is then overlaid with a fully floating floor deck, onto which the floor finish is applied. In the case of wooden floors, this can be laid directly on to the insulation to minimise height build-up and maximise the heating output.

Low profile

When it comes to retrofit applications where you’re working with the existing floor construction, before installing the underfloor heating system it’s key to ensure that the concrete or timber-based sub floor is flat and level. Then for the underfloor heating itself, a slim underfloor heating system is desirable to ensure minimal floor build up.

The lowest profile systems will also incorporate insulation, such as AmbiDeck 18 where the high-density 18mm XPS insulation panel is also cement-coated, making it rigid and durable. Grooves are then pre-formed in the panel to take the underfloor heating pipework, with a radius return grooved into each panel.

To keep the floor build up minimal, you also need to consider the floor finish. Tiles and wood flooring can be laid directly over most, insulated, low-profile systems – removing the need for an additional layer beneath the floor finish. However, other finishes such as carpets or vinyl will require an intermediate board layer, prior to the finish being installed – adding to the build-up.

Bespoke

Even if your project has specialist design and installation requirements, thanks to the flexibility of underfloor heating, with the right design and installation the property can benefit from an efficient system.

For solid wall properties as well as for some new builds and extensions, for example, a highly specialised ‘breathable’ system may be required, such as AmbiSublime which has been designed for use on lime screeded floors. It also boasts excellent environmental credentials and ease of installation, despite the bespoke nature of the solution.

The key with any underfloor heating installation is to work with a supplier which can assist with the design, including pipework layouts and heat output calculations – and, if necessary, create a bespoke system to suit your specific project specifications. That way you can ensure a smooth installation and maximum output from the finished system.