Adrian Pargeter, Head of Technical and Product Development at Kingspan Insulation Limited, gives his view on the risks posed by toxic fumes which can potentially be emitted during a fire.

Ensuring properties provide adequate protection for occupants in the event of a fire is a major concern for all developers. In recent months, there has been considerable discussion about the risks posed by toxic fumes which can potentially be emitted during a fire. To help specifiers to better understand the possible risks, leading fire testing experts — Exova Warringtonfire — conducted a detailed study to assess how wall insulation products and general room contents contribute to the development of a fire and production of toxic gases.

Hazards

The most obvious danger presented by fire is heat. In a modern domestic room, small fires can quickly become fully developed, reaching flashover in a matter of minutes (this is the point at which the flammable gases released by burning materials within a room near-simultaneously ignite).

Smoke presents a further hazard both to those directly exposed to a fire, and to occupants in other rooms or in the process of evacuating. Inhalation of the toxic fumes and harmful particles within this smoke is known to cause or contribute to the majority of fatalities in fires in domestic properties.

Evaluation

Due to the complexity of fires, it is difficult to assess how room contents and construction products may contribute to smoke toxicity. The smoke produced by burning materials, and the resulting risk to occupants, are strongly dependent on location of the burning material, the fire scenario (e.g. room size, temperature, ventilation), and exposure time.

To shed some light on this issue, PU Europe commissioned Exova Warringtonfire to carry out a detailed study looking at the relative contribution of both room contents and building fabric insulation on heat release, smoke production and toxic gases for a fire starting in a furnished room.

Testing

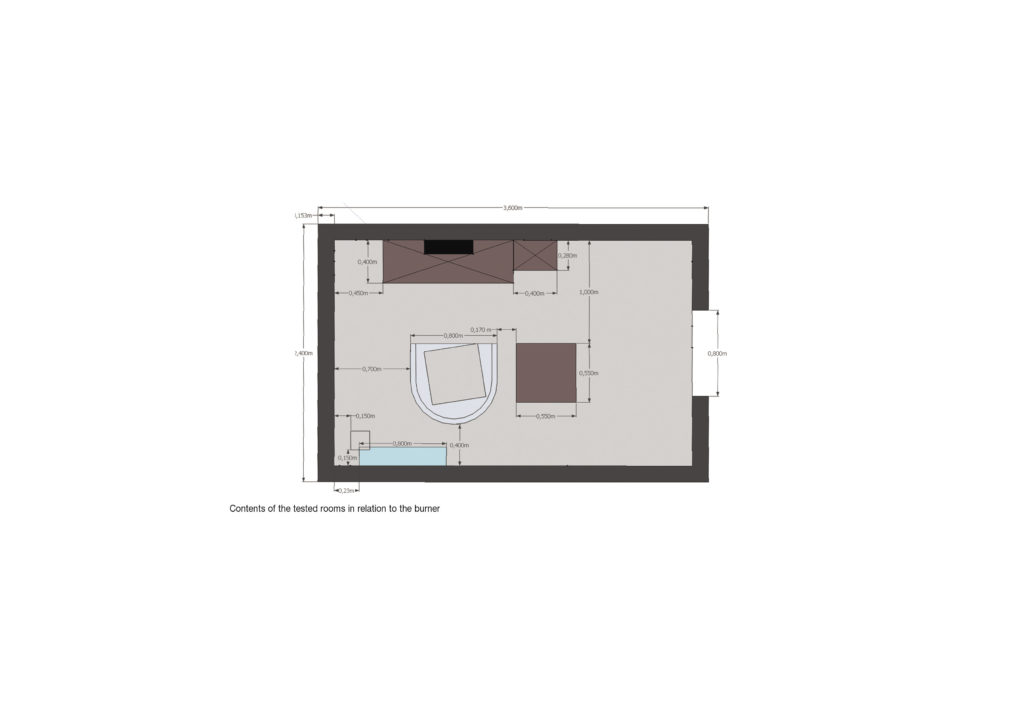

The research was carried out within a full-scale test room designed to the specifications given in ISO 9705 (Image 1).

The room was furnished with curtains, an armchair, small table, TV with bench and bookcase. All walls (apart from the wall containing the doorway) were insulated. To better understand the contribution of the insulation material within the scenario, two tests were conducted which differed only in the wall insulation material, one with polyisocyanurate (PIR) insulation and the other with rock mineral fibre insulation.

To achieve a fair comparison, the insulation thicknesses differed (80 mm PIR vs.140 mm rock mineral fibre) so that the wall U–values in both tests were identical. The insulation materials were installed between 50 mm wide wooden battens at 570 mm centres and were lined with a 12.5 mm layer of plasterboard.

The scenario used a 30 kW gas burner to simulate a waste paper basket fire which ignites the curtains and spreads to the armchair within the first five minutes of the test. The burner was positioned in the corner of the room beneath the curtains. A power socket was also added to a wall near the burner to provide a realistic weak spot in the plasterboard lining.

The burner was ignited and allowed to burn for five minutes before being turned off. The development of the fire was then observed. The time of ignition for the armchair was chosen as the starting point for the analysis.

Results

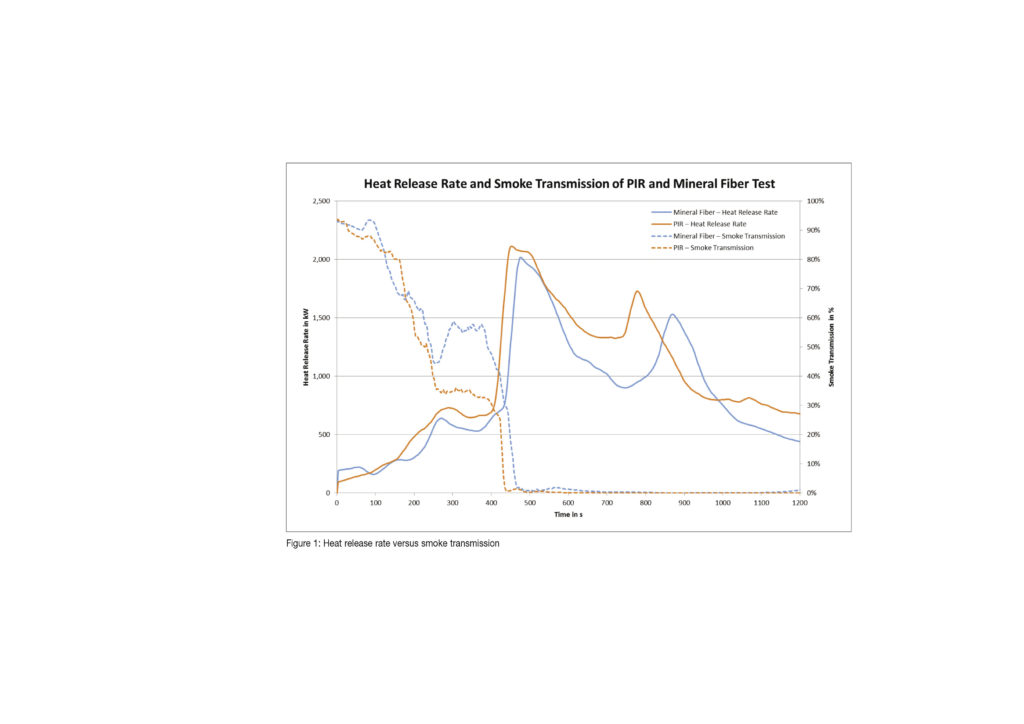

Analysis of the heat release from the tests showed that flashover was reached 7.24 mins after the ignition of the armchair in the rock mineral fibre test and 6.55 mins in the PIR test. In both cases, flashover was caused by burning contents alone as the plasterboard had not yet been breached.

As Graph 1 shows, a second peak heat release was observed at between 13 – 15 mins, the fire then decayed. The insulation materials were not directly exposed to flame until about 20 minutes into the test when the plasterboard first began to crack, and no further heat peaks were recorded after this point. The heat release rates for both tests fell below 50 kW after around 50 mins.

The following gases were measured during the test:

• carbon monoxide;

• carbon dioxide;

• hydrogen cyanide;

• formaldehyde;

• acrolein;

• sulphur dioxide;

• hydrogen chloride; and

• nitrogen oxides.

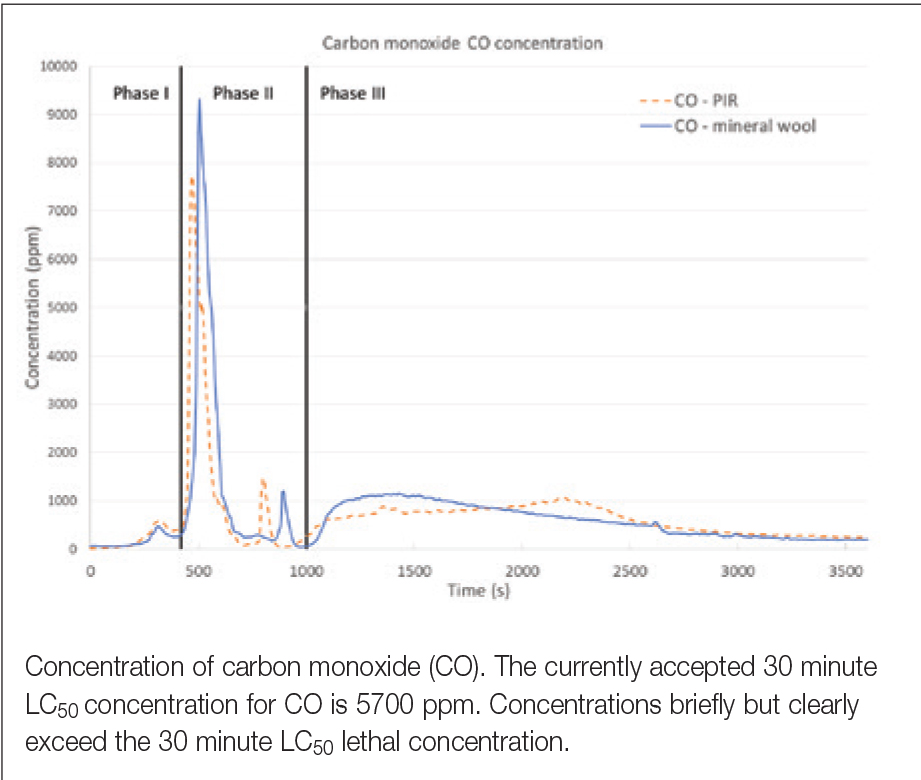

A sharp peak in the concentration of the toxic gases was reached when flashover occurred. At this stage, the concentrations of carbon monoxide and hydrogen cyanide briefly but clearly exceeded lethal concentrations.

In the decay phase, carbon monoxide concentrations were very similar in both tests. Contribution of gases from the insulation materials occurred very late and only after much higher concentrations were measured from the burning contents. For rock mineral fibre, formaldehyde and acrolein concentrations were higher in the decay phase whilst for PIR insulation, hydrogen cyanide concentration was higher. However, all concentrations measured in the decay phase were well below lethal concentrations.

Measurements clearly showed that the early stages of the test, when the insulation was not yet involved in the fire, contributed most to human toxicity.

Raising Standards

It is important to note that the Exova Warringtonfire study looks only at one scenario and all observations made are valid solely for its specific configurations. Nevertheless, the results suggest that it is sensible for developers who wish to ensure a high level of fire safety in their properties to focus efforts on installing effective detection, prevention and evacuation systems and ensuring that any building contents achieve a high standard of fire resistance.