Stuart Wood, Product Manager for Heat Networks at Polypipe Building Products, explains how manufacturers can help developers opting to use district heating in housing developments.

With the legislation restricting the use of gas boilers in new-builds looming ever closer, interest in heat pumps and heat networks is rising as developers look for more energy-efficient solutions.

In fact, the Clean Growth Strategy (published by the UK Government) predicts that heat networks will meet 20% of demand for heating and in buildings by 2050. Heat networks, also called district heating, can use any energy source which includes renewables and efficient heat pumps.

Heat networks deliver hot water from a central source to individual properties through a network of insulated pipes. Although a heat network can cover an area the size of a large town it is more often used to heat small blocks of flats and small to medium-sized housing developments.

Despite the interest in – and demand for – heat networks growing exponentially, there are still many who are unfamiliar with the systems, the installation details or with some of the options available when planning a heat network.

If you are looking for advice for a district heating project, talk to a trusted manufacturer who should be able to advise you on the ideal products and the key points that need to be covered during installation.

At Polypipe Building Products we have single and double heating insulated pipe which is manufactured specifically for use with heat networks. Polypipe can advise on which pre-insulated pipes are needed for each part of a project as well as any testing that needs to be done.

Pre-insulated pipes

Both the single and double medium pipes are primarily intended for the transport of heating water in buried distribution networks. The double pipes combine both the flow and the return medium pipes in the same jacket pipe.

Both are hyper flexible and made from cross-linked polyethylene PE-Xa and colour coded to enable easy identification of flow and return during installation, even with mounted dust or shrink end caps

The multilayer thermal insulation is made from cross-linked, microcellular polyethylene PE-X foam with a water-repellent closed cell structure, characterized by its durable, non-ageing insulation performance, and its permanent elasticity, maximizing and maintaining the thickness of the insulation layer, even after bending multiple times.

The high-grade, black coloured UV-resistant, double walled, corrugated HDPE jacket pipe shields the pre-insulated piping system against mechanical impacts and moisture, whilst maintaining maximum flexibility.

Installation process

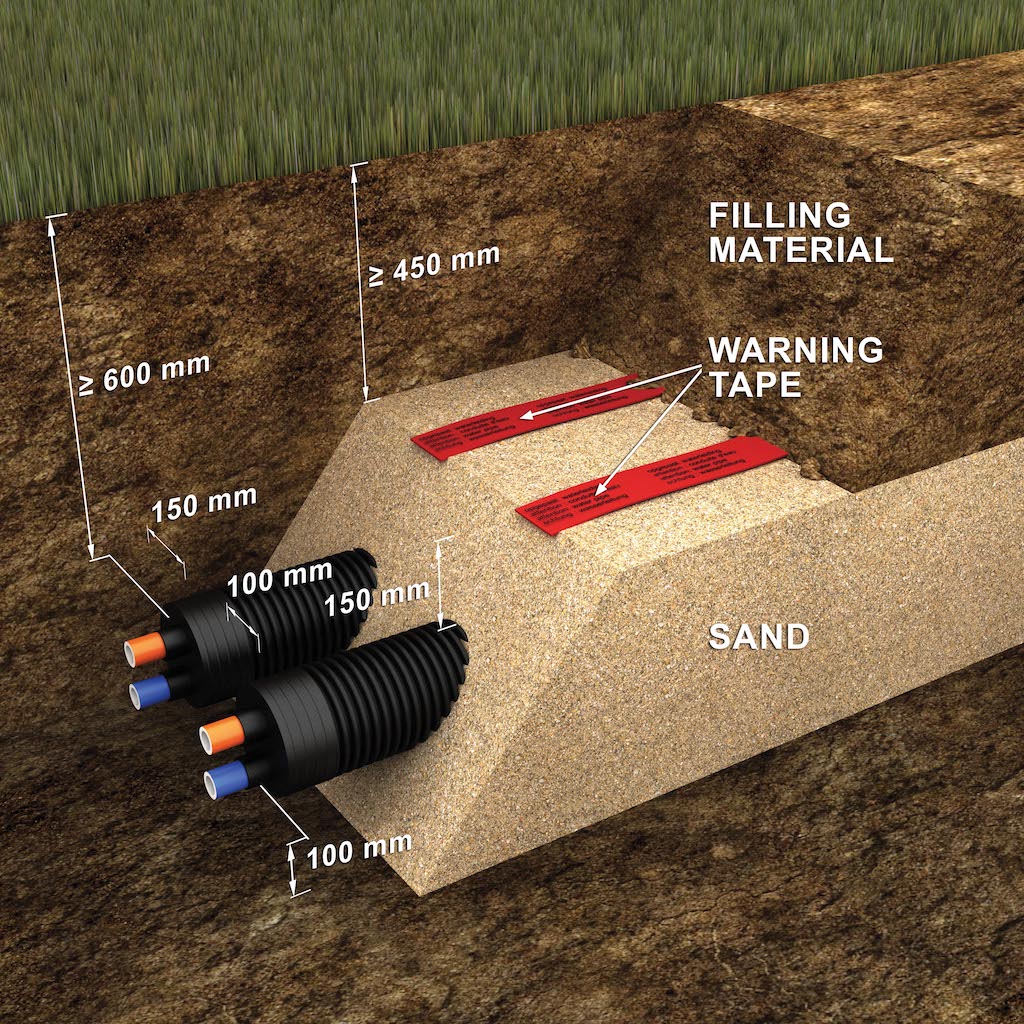

The pre-insulated pipe can be laid into the trench directly from the coil but, to avoid damaging the outer HDPE jacket, always remove all sharp objects from the ground and lay the pipe in a sand bed.

When laying larger dimensions and lengths, pulling devices such as winches or tail-end rollers may be used. Always connect these devices to the medium pipe.

Roll the pipe alongside or straight into the trench, ensuring that you keep the stated bending radius. For double pipes the flow and return must be laid on top of each other.

We recommend that you install identification markers on the pipe network and all branches – and you must conduct the pressure test and before backfilling.

Partially fill the trench with a first layer and backfill only after fully covering the pipes with sand, respecting the minimal layer dimensions as indicated in the trench dimension drawing.

The filling material must be compacted layer per layer until 500mm, at which point the coverage may be compacted by machine.

The installation of adequately anchored fix points at the system’s extremities (typically at wall penetrations) is mandatory. This to secure the connected plumbing against the potential impact of the systems dilatation forces (thermal expansion/retraction).

Although this guidance will be well-established for some, the increase in heat network projects will mean more developers and contractors will have to become familiar with the guidelines on the systems.

An established manufacturer should be able to offer broad advice on heat networks.