Matthew Evans, Head of Technical GB at Kingspan Insulation UK, explores how the quality of major refurbishment projects can be improved.

In recent months, there has been considerable criticism of office-to-residential conversions under the permitted development scheme in England. Critics have highlighted flats as small as 13m2 or that have no windows and the Royal Institute of Chartered Surveyors (RICS) has called for a return of full planning control.

At the same time, conversions offer a valuable route to repurposing underused buildings, meeting the demand for housing in a manner that is much less carbon intensive than demolishing and rebuilding. The question is, how can we maintain quality in these redevelopments?

The RICS report points to the Netherlands where local and national government work with developers, providing toolkits with advice and guidance, actively identifying buildings with development potential whilst maintaining clear minimum quality standards. This approach allows them to deliver a higher rate of office-to-residential conversion than the UK without significant de-regulation.

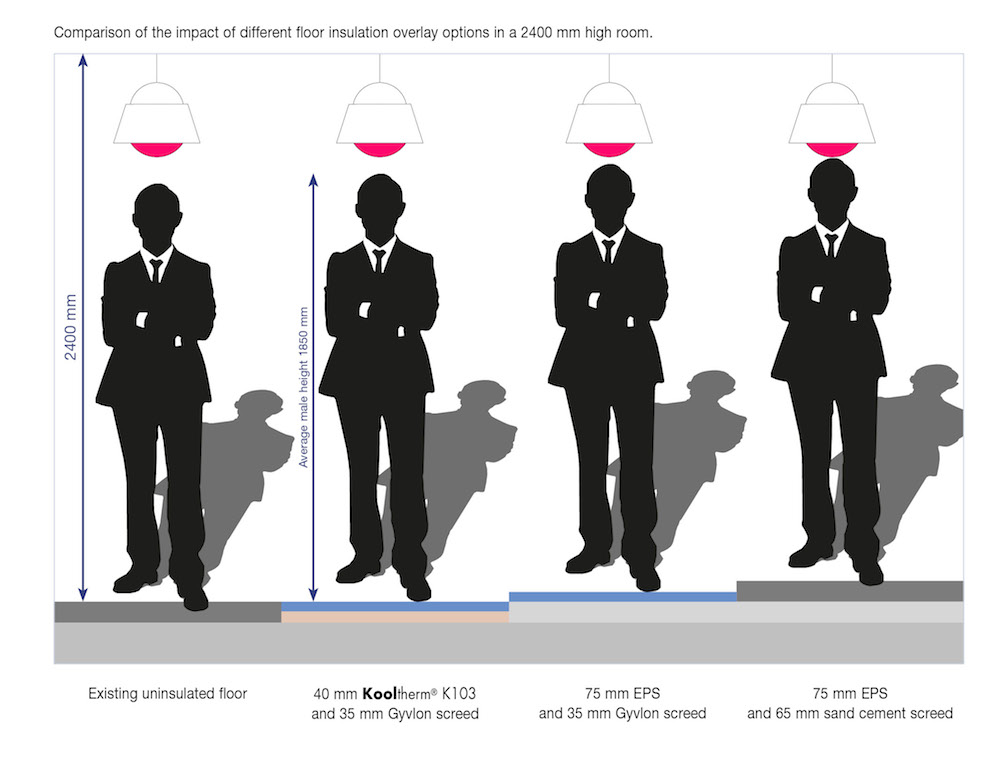

Energy performance is another key concern. Many older buildings are poorly insulated, and to meet Building Regulation/Standard requirements it may be necessary to retrofit insulation. This can prove challenging above solid floors as adding insulation can reduce headroom. Research has now shown that by installing premium performance phenolic floor insulation, it is possible to meet regulatory requirements whilst retaining floor-to-ceiling heights.

Considerations

Research has shown that rooms with higher ceilings can give occupants a greater feeling of space and may also improve the desirability of a property. Many solid floored buildings were constructed in the post-war period and have a smaller floor-to-ceiling height than their predecessors. As such, any loss in headroom should be avoided.

From a practical perspective, changing floor heights is likely to mean that fixtures and services must be raised. This can significantly increase the cost and complexity of the work.

For these reasons, it makes sense to consider insulation with lower thermal conductivities. The lower the thermal conductivity of a material, the more effective it is at preventing heat transfer from conduction. This can allow a desired U-value to be achieved with a slimmer thickness of insulation.

To understand how the choice of insulation can impact both the overall cost of refurbishment work and floor-to-ceiling height, Kingspan Insulation asked Currie & Brown to carry out a cost analysis.

Research

The analysis considered a property with an 84 m2 floor with a perimeter/area ratio of 0.42 and a floor-to-ceiling height of 2,475mm. The existing floor build–up consisted of a damp-proof membrane, 100mm solid concrete ground bearing slab and 75mm sand and cement screed.

Two refurbishment scenarios were considered:

- The sand and cement screed was removed and replaced with insulation and either a 35mm liquid screed or 65mm sand and cement screed.

- The existing floor was excavated and replaced with a 100mm concrete slab, insulation and the sand and cement or liquid screed.

Two different types of insulation were compared in each build-up:

- premium performance phenolic insulation (thermal conductivity: 0.018 W/m.K); and

- expanded polystyrene (EPS) rigid insulation (thermal conductivity: 0.038 W/m.K).

All constructions were designed to achieve a maximum U-value of 0.25 W/m².K (complying with the current recommendations in England and Wales).

Results

The results from the cost analysis are summarised in the table below.

| Floor build-up | Total cost of construction | Floor-to-ceiling height | Change in ceiling height |

| Scenario 1 – Existing sand and cement removed and replaced with: | |||

| 35 mm high–performance liquid screed and 40 mm phenolic insulation | £7,060 | 2,475 mm | 0 mm |

| 65 mm sand and cement screed

and 40 mm phenolic insulation |

£6,481 | 2,445 mm | -30 mm |

| 35 mm high–performance liquid

screed and 75 mm EPS |

£6,869 | 2,440 mm | -35 mm |

| 65 mm sand and cement screed

and 75 mm EPS |

£6,327 | 2,410 mm | -65 mm |

| Scenario 2 – Existing floor excavated and replaced with a 100 mm concrete slab and: | |||

| 65 mm sand and cement screed

and 40 mm phenolic insulation |

£21,568 | 2,475 mm | 0 mm |

| 65 mm sand and cement screed

and 75 mm EPS |

£22,230 | 2,475 mm | 0 mm |

The research shows that it was considerably more cost effective to remove and replace the screed layer rather than excavating the entire slab. When adopting this approach, the phenolic insulation specification with liquid screed was the only construction which allowed existing floor-to-ceiling heights to be retained. This also avoids potential remedial costs relating to altering floor heights which were not considered within the analysis.

In practice

The practical benefits of installing more thermally efficient insulation were shown during the conversion of the former Royal Military Academy overlooking Woolwich Common.

Durkan oversaw the conversion of the Grade II* listed building into 328 apartments. They consulted closely with Historic England to ensure this work was sympathetic to its character whilst meeting current energy efficiency requirements. The building’s uninsulated beam and block floor prevented the team from digging down to make space for floor insulation. To effectively insulate this area whilst retaining existing threshold levels a Vacuum Insulation Panel (VIPs) system was specified.

VIPs typically feature a microporous core which is evacuated and sealed within a gas-tight envelope, allowing them to achieve thermal conductivities as low as 0.007 W/m∙K. Rigid insulation infill panels of the same thickness are supplied with the systems and can be cut to allow penetrations, fit around the perimeter and to fill awkward gaps between the VIPs panels. This innovative design allowed the target floor U-value to be met with an insulation thickness of just 30 mm.

Better Buildings

Conversions present rich opportunities for developers looking to expand their portfolios. By taking time to consider the design of the building, it should be possible to create homes which are fit for purpose and attractive.

The energy performance of the building should be assessed as part of this. As the Currie & Brown research shows, by fitting more thermally efficient insulation it is possible to reduce solid floor construction thicknesses – providing a cost-effective means of retaining headroom whilst improving the overall fabric performance.