Richard Price, Technical Director at Catnic, provides guidance for property developers on why it is imperative to select high quality plasterbead and mesh products that are fit for purpose.

The external finish of a property is, of course, vital. From a practical perspective, it needs to help protect the building envelope against the elements and understandably, the external finish is going to have a significant impact on the property’s overall aesthetic and general kerb appeal.

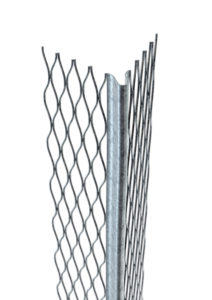

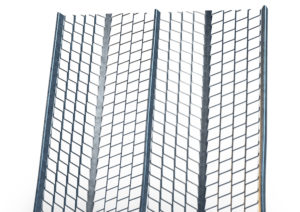

Plasterbead and mesh products can play a vital role in achieving these requirements. They will prevent a rendered surface from cracking, increasing its durability and longevity as well as offering a reliable method of achieving the slick, professional finish that potential owners would expect of any rendered facades. Therefore, accurate selection is absolutely crucial.

Compliance and Responsible Sourcing

Compliance and Responsible Sourcing

As with any building component, start with the basics and ensure that the product has a CE marking. For external applications, developers should select solutions in accordance with BS EN 13914-1:2016 Code of Practice, which covers the design, preparation and application of external rendering. Failing to comply with these standards or choosing a plasterbead manufactured from an incorrect material could lead to the external envelope becoming exposed. Developers have a duty of care to ensure that the products selected are legal and will perform as intended.

Furthermore, it is advisable to look for products that comply with BES 6001. This can provide the assurance for the property developer, contractor and eventual owner that the products meet the Government’s standards for responsible sourcing. BES 6001 certified plasterbead products can help developers obtain credits under the Responsible Sourcing of Materials section of BREEAM.

Consider location and conditions

Different materials are suitable for different applications, which means it is important for developers to understand how to match the right product with the right surface and environment. The use of an incorrect material type carries a risk of corrosion and brings the likelihood of staining through the render resulting in the need for expensive remedial repair and replacement work to correct the problem.

Choosing the right plasterbead can be difficult, especially as there are so many available on the market. Leading manufacturers should be able to provide plasterbeads in a range of materials, including stainless steel, PVC-u, as well as galvanised beads for any internal requirements.

For external applications and for properties in areas of high moisture, or where the risk of damp is present, a stainless steel or PVC-u solution is ideal. Historically, PVC-u solutions have been more commonly used abroad. However, with the UK’s climate changing and weather becoming more extreme, PVC-u solutions are increasingly common in Britain. An additional bonus for developers is that PVC-u solutions can be more cost-effective than stainless steel alternatives and also help to eliminate cold bridging.

If a cement-based render has been applied then a stainless-steel plaster bead solution is the optimum choice.

Checking quality and longevity

In the past developers, and the contractors installing the products, might not have considered there to be much differentiation between one brand of plasterers’ bead and another. With ‘equal or equivalent to’ specifications reinforcing this idea – the door is unfortunately left open for quality compromises that can fall short of the original design intention.

As such, wherever possible opt for a reputable manufacturer. In addition, a simple but effective means of establishing quality is checking rigidity. The more rigid a plasterers’ bead is, the easier it will be to retain the plumbline and achieve a precise finish.

Above all, it’s important for developers to take the time to match the right solution with the relevant environment. Remember that there is no equal, or equivalent specifications when environmental factors are not accounted for.

Don’t mix your materials

Once the product has been selected another important factor to take into account is the type of fixing. Best practice means avoiding mixing different material types, For example, if a stainless steel plasterers bead is being used, then ensure the specification does not include any zinc mechanical fixings. This would potentially result in a chemical reaction that leads to the breakdown of the fixing and ultimately – the plasterers bead could break away from the surface.

Understanding installation best practice

Understanding installation best practice

If possible, gain advice from the manufacturer themselves. Even the best product can run into issues if it has not been installed correctly. For example, when dealing with large sections of external render, best practice dictates installing adequate movement bead panels, no more than 5 metres apart and never over a structural joint. This will allow for any necessary movement of the building without damaging the render finish.

Contributing to a perfect finish

When it comes to building a property, the devil is in the detail, and plasterbead and mesh has to be fit for purpose and of a high quality. For external applications, an incorrect product can have serious ramifications for the longterm success of the building’s performance and cheap alternatives represents a false economy for developers looking to build high-quality projects.

When looking to find an external plasterbead solution, developers needn’t look any further than Catnic. The company has provided steel and PVC-u construction products to some of the nation’s leading residential as well as commercial projects.